Mercedes 2626 AK 6x6

Moderator: Moderatoren

Re: Mercedes 2626 AK 6x6

The next day, I easily removed the pressure plate with the aid of the winch and then carefully removed the flywheel. At inspection, the race was nice and evenly polished, as it should be, but there were clear traces of oil leaking from the retainer that, on its turn, looked pretty healthy too. Hmm…

Eduardo had to go to Valparaíso himself to pick some spares so he offered himself fully hearted (!?) to get a new retainer for me profiting of the trip.

What to do in the meantime? He had given me an advice on what to do to extract the pin of the intermediary gear some days ago after seing the striking method did not work, but I had not given it a chance… until then.

Adapting things a little to follow his idea, I cut the sliding hammer and left the threaded extreme welded to the bolt to use it as a puller shaft. A couple of pieces of discarded and broken bearings served as spacers and the top of the self-made extractor gave stand and grip for the nut. Easy.

And it actually was. Uh.

Began to turn the big wrench clockwise and, after a minimum effort compared with the sliding hammer madness, there was a sudden release and the pin popped out from the surface of the gear housing. Great!

I was thinking on using the heating stuff to take the pin out, but this was far more easy and less destructive. Oh, I really like my brother in law!

Actually, it was only the beginning of the extraction that required a lot of other maneuvers and improvised spacers and patience, though, after a little while, the bloody pin was finally out in my hands and the way was free to access to all the bolts that kept the gear box fixed to the gear housing. Good.

Carmen was happy too and wasted not time to remind me to follow his brother’s advices, always. I know, I know…

Covered or wrapped all the parts and pieces, swept the floor and made order for good, preparing the place for the disassembling of the gear box that would probably take place in the next working session.

I was happy, and everything went far more easy than expected, beginning for the disassembling of the engine.

Sometimes a seemingly big job is just the fear of the annoyance and hassle you assume it will bring to you, and turns out it is nothing more than a job, another simple job you have to face and accomplish with the best of moods.

Everything happens for a reason.

Greetings from Chile.

Eduardo had to go to Valparaíso himself to pick some spares so he offered himself fully hearted (!?) to get a new retainer for me profiting of the trip.

What to do in the meantime? He had given me an advice on what to do to extract the pin of the intermediary gear some days ago after seing the striking method did not work, but I had not given it a chance… until then.

Adapting things a little to follow his idea, I cut the sliding hammer and left the threaded extreme welded to the bolt to use it as a puller shaft. A couple of pieces of discarded and broken bearings served as spacers and the top of the self-made extractor gave stand and grip for the nut. Easy.

And it actually was. Uh.

Began to turn the big wrench clockwise and, after a minimum effort compared with the sliding hammer madness, there was a sudden release and the pin popped out from the surface of the gear housing. Great!

I was thinking on using the heating stuff to take the pin out, but this was far more easy and less destructive. Oh, I really like my brother in law!

Actually, it was only the beginning of the extraction that required a lot of other maneuvers and improvised spacers and patience, though, after a little while, the bloody pin was finally out in my hands and the way was free to access to all the bolts that kept the gear box fixed to the gear housing. Good.

Carmen was happy too and wasted not time to remind me to follow his brother’s advices, always. I know, I know…

Covered or wrapped all the parts and pieces, swept the floor and made order for good, preparing the place for the disassembling of the gear box that would probably take place in the next working session.

I was happy, and everything went far more easy than expected, beginning for the disassembling of the engine.

Sometimes a seemingly big job is just the fear of the annoyance and hassle you assume it will bring to you, and turns out it is nothing more than a job, another simple job you have to face and accomplish with the best of moods.

Everything happens for a reason.

Greetings from Chile.

- tooFATtoDRIVE

- Selbstlenker

- Beiträge: 180

- Registriert: 2017-06-16 20:46:29

Re: Mercedes 2626 AK 6x6

Pairo, given the uncertainty of the future as we all are experiencing right now, it is great to see one contanst, unchanged and ongoing activity - your excellent, informative, well-documented and very very interesting posts! These really keep the madness from creeping in my mindset. It is great to see constant progress!

Re: Mercedes 2626 AK 6x6

Thanks for all your contributions Pairo!

Keep save and healthy.

Keep save and healthy.

Mein blogs: http://rundhauber.eu/ und http://lp2223.com

Re: Mercedes 2626 AK 6x6

Guys:

Life is pretty much uncertain, it has always been. We just tend (or pretend) to forget it.

We have to dream, work, love, laugh, and travel as we and the world will stay forever, for it all could end today.

Keep up with your lives. Glad to help.

Pairoa

Life is pretty much uncertain, it has always been. We just tend (or pretend) to forget it.

We have to dream, work, love, laugh, and travel as we and the world will stay forever, for it all could end today.

Keep up with your lives. Glad to help.

Pairoa

Re: Mercedes 2626 AK 6x6

A few more words and pictures, hoping everyone is fine:

Another autumn had arrived, though the poplars had got rid of their leaves a little prematurely because of the dryness. Here the seasons tend to shift abruptly, but this year we had days of extreme heat, then cold days followed by more very hot days, alternating randomly as if there was no big order. Weather is crazy.

At least the air was fresher and you could see some clouds covering part of the morning sky, and the dogs were always as happy as myself to go running.

I went to pick the new adjusting cone for the gear shifting rod to Verardo’s machineshop and got the shiny piece that, unfortunately, looked better than it screwed into the clamping piece. I would have to take it back for a repass, but that would have to be later in time as I had not precisely much time to go around.

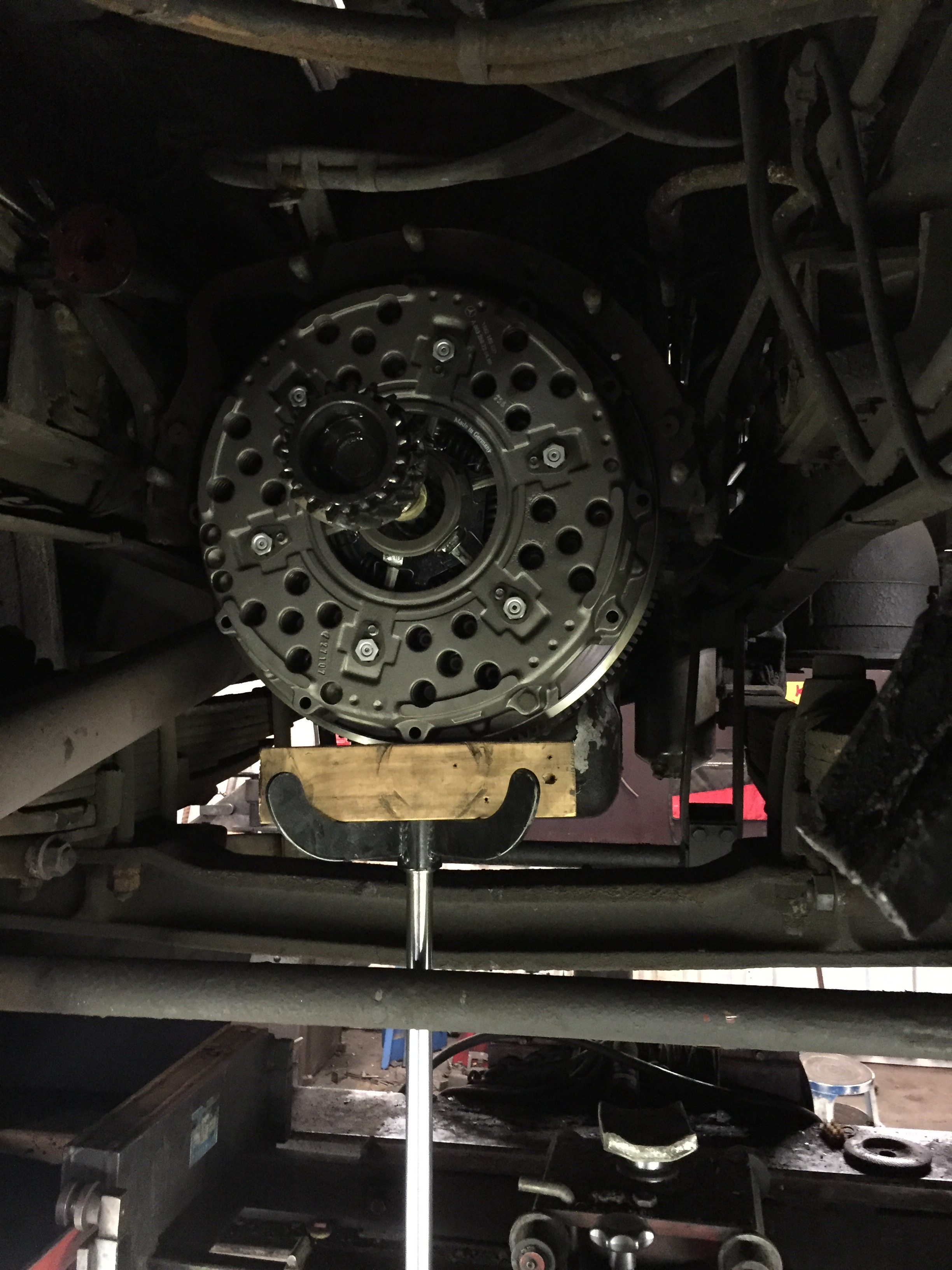

Eduardo, my brother-in-law, brang the new retainer for the pressure plate profiting of one of his trips to get spares to keep on with his business. The retainer was the same brand but looked more robust.

After cleaning all the pieces and surfaces for good, I removed the old retainer, that in fact looked like new, and made sure there was no damage to the housing. If something was wrong it had to be the retainer.

If I inadvertently damaged the retainer, it had to be during the installation of the pressure plate when assembling the engine, some time ago. So, this time I proceeded very carefully and hung the plate from the winch and used two extension bars from the tool sets that fitted perfectly to guide the plate smoothly into place. Easy.

I had to go back in time to look for the torque settings for the bolts that secured the plate to the cranckshaft, but finally found them in an e-mail from 2011.

Then I put the adapter flywheel back on and adjusted the disc position with a steel strut, by eye only, trusting it would be a just one-time maneuver.

And it was. The intermediate shaft went in a perfectly centered clutch disc and the bell housing was secured with the many bloody bolts, with the appropriate torque, of course.

I bolted the engine supports to the bell housing, hung the engine from the winch, just enough to allow removing the wooden pieces from under the exhaust manifold, and then installed the clutch cylinder back on.

And then the oil leak issue of the back of the engine was solved. Now it was a matter of cranking the engine and see how it worked, pretty confidently… with fingers crossed.

The gearbox, oh yes. Well, I got the portable winch near and rescued the chains from a forgotten box in the corner of the shop. The chains were more robust than the ropes and I wanted to use them to hang the gear box while separating it from the gear housing, but it was soon clear that they would damage the pretty sharp metallic edges, no matter what kind of arrangement I made with wood pieces. So, I got some ropes and hung the heavy box with them prior of taking the last bolts that kept both pieces together.

Naturally, there were among them some Allen bolts for which there were no appropriate Allen sockets, so I had to go out to buy some.

Then, after removing the bolts and with the aid of some precisely aimed strikes, the big parts separated nice and quietly.

Another autumn had arrived, though the poplars had got rid of their leaves a little prematurely because of the dryness. Here the seasons tend to shift abruptly, but this year we had days of extreme heat, then cold days followed by more very hot days, alternating randomly as if there was no big order. Weather is crazy.

At least the air was fresher and you could see some clouds covering part of the morning sky, and the dogs were always as happy as myself to go running.

I went to pick the new adjusting cone for the gear shifting rod to Verardo’s machineshop and got the shiny piece that, unfortunately, looked better than it screwed into the clamping piece. I would have to take it back for a repass, but that would have to be later in time as I had not precisely much time to go around.

Eduardo, my brother-in-law, brang the new retainer for the pressure plate profiting of one of his trips to get spares to keep on with his business. The retainer was the same brand but looked more robust.

After cleaning all the pieces and surfaces for good, I removed the old retainer, that in fact looked like new, and made sure there was no damage to the housing. If something was wrong it had to be the retainer.

If I inadvertently damaged the retainer, it had to be during the installation of the pressure plate when assembling the engine, some time ago. So, this time I proceeded very carefully and hung the plate from the winch and used two extension bars from the tool sets that fitted perfectly to guide the plate smoothly into place. Easy.

I had to go back in time to look for the torque settings for the bolts that secured the plate to the cranckshaft, but finally found them in an e-mail from 2011.

Then I put the adapter flywheel back on and adjusted the disc position with a steel strut, by eye only, trusting it would be a just one-time maneuver.

And it was. The intermediate shaft went in a perfectly centered clutch disc and the bell housing was secured with the many bloody bolts, with the appropriate torque, of course.

I bolted the engine supports to the bell housing, hung the engine from the winch, just enough to allow removing the wooden pieces from under the exhaust manifold, and then installed the clutch cylinder back on.

And then the oil leak issue of the back of the engine was solved. Now it was a matter of cranking the engine and see how it worked, pretty confidently… with fingers crossed.

The gearbox, oh yes. Well, I got the portable winch near and rescued the chains from a forgotten box in the corner of the shop. The chains were more robust than the ropes and I wanted to use them to hang the gear box while separating it from the gear housing, but it was soon clear that they would damage the pretty sharp metallic edges, no matter what kind of arrangement I made with wood pieces. So, I got some ropes and hung the heavy box with them prior of taking the last bolts that kept both pieces together.

Naturally, there were among them some Allen bolts for which there were no appropriate Allen sockets, so I had to go out to buy some.

Then, after removing the bolts and with the aid of some precisely aimed strikes, the big parts separated nice and quietly.

Re: Mercedes 2626 AK 6x6

Some of the built-in circuits for the lubrication were clogged by the filthy gelly oddity found everywhere in the gearbox. Better for the future of the gears having disassembled it.

The gear box was a pretty heavy bastard, though I managed to accommodate it to have it resting on the side without taking it out from the winch. That way the main shaft was exposed upwards, ready to be taken out. Ready?

Soon after putting the gear box on a stable platform on the same trolley, I heard Carmen shouting it was time to go. Another week had passed and the progresses were quite slow, though at least there were progresses. I was happy.

Covered it all and made order. I had been not working in the Merkabah on the weekends as my full attention had shifted to the new house, still in the building process, with the classic delays and problems related to the building itself and the contingency due to the bloody viruzzz.

The same contingency almost left my father with no job, as his clients requested a pilot less than 60 years old because of the risk of the covid 19. Fortunately, experience and common sense prevailed and he went to work far north.

I put a really beautiful picture of the helo taken by one of his passengers with a serious camera while passing by, with the massive and gorgeous northern Andes as framing.

At the shop, next monday, to remove the main shaft and the gears from the box I needed to remove first the big bearing on the back. It was big and stuck like an avalon, as expected. Working carefully with the sledgehammer and a piece of bronze I reached to get it out of the case, milimeter by milimeter, just by using stoneage tech, but there was still a long way to go before removing it from the shaft itself. Hmm…

Eduardo approached and suggested to use hydraulic power instead of Neanderthalis strenght, again. I sighed and looked around and found the once projected support for the jack to push the kingpins on the steering knuckles. The ugly and odd looking thing actually was never used because the pins were put, frozen, by the sole push of the hand. It seemed a good idea at that time, though.

I made some measurements, cut the two pillars according to them and fixed the hydraulic jack pretty simply with a couple of pieces of steel firmly tacked to the base.

The gear box was a pretty heavy bastard, though I managed to accommodate it to have it resting on the side without taking it out from the winch. That way the main shaft was exposed upwards, ready to be taken out. Ready?

Soon after putting the gear box on a stable platform on the same trolley, I heard Carmen shouting it was time to go. Another week had passed and the progresses were quite slow, though at least there were progresses. I was happy.

Covered it all and made order. I had been not working in the Merkabah on the weekends as my full attention had shifted to the new house, still in the building process, with the classic delays and problems related to the building itself and the contingency due to the bloody viruzzz.

The same contingency almost left my father with no job, as his clients requested a pilot less than 60 years old because of the risk of the covid 19. Fortunately, experience and common sense prevailed and he went to work far north.

I put a really beautiful picture of the helo taken by one of his passengers with a serious camera while passing by, with the massive and gorgeous northern Andes as framing.

At the shop, next monday, to remove the main shaft and the gears from the box I needed to remove first the big bearing on the back. It was big and stuck like an avalon, as expected. Working carefully with the sledgehammer and a piece of bronze I reached to get it out of the case, milimeter by milimeter, just by using stoneage tech, but there was still a long way to go before removing it from the shaft itself. Hmm…

Eduardo approached and suggested to use hydraulic power instead of Neanderthalis strenght, again. I sighed and looked around and found the once projected support for the jack to push the kingpins on the steering knuckles. The ugly and odd looking thing actually was never used because the pins were put, frozen, by the sole push of the hand. It seemed a good idea at that time, though.

I made some measurements, cut the two pillars according to them and fixed the hydraulic jack pretty simply with a couple of pieces of steel firmly tacked to the base.

Re: Mercedes 2626 AK 6x6

Then, drilled a couple of holes on the plates that served as stabilizers to match the bores on the cage to have a cleaner and tougher grip, and hung the jack to finally weld the pillars perpendicular to the holding plates with a pretty thick welding. And that was it: another Pairoa’s port-o-power.

But, always the big BUT, the jack did not work horizontally, as you probably all knew. Well, I didn’t. So, I had to hang the whole bunch of kilos of metal from the winch and put it vertically, or almost vertically to make the jack work.

It was then just a matter of applying a little pressure on the shaft, only the six millimeters allowed by the play between the gears, change progressively the thickness of the retainers, and eventually the bearing fell soundly on the jack. Took some time, but it worked. Thanks again, brother.

I got the neo-extractor free from the gear box and put the later back on the trolley to keep on with the disassembling.

Removing the shaft with all the gears from the box was relatively easy thanks to the winch and the ropes. Christ, how heavy they are!

Once on the working tray, I made a vain try to take the front bearing out using the extractor. No way, and I knew it. Grabbed the powergrinder and the screwdriver and destroyed the outer bronze cage and took the rollers out with no mercy. I then grinded the inner raceway until it was so thin that a couple of strikes broke it loose. I was pretty afraid of damaging the shaft so it took me quite a while to get to that point.

Once the bearing was out, the locking nut was exposed, another big task in itself. It was pretty clear, again, that the sliding sleeve was freely moving over the synchronizer’s hub as there were no end pieces nor springs at sight.

I will save you from the carnage of the removal of the locking nut, just tell that I finally asked Eduardo to help me to take it out as I was not able to do it without suffering. The chisel work is definitely not for me.

The following was a surprise: I removed the synchronizer hub and found that the cone on the side of the 3rd gear was also broken, in many pieces. I had seen before one of the little broken pieces when first opening the lateral cover of the the gear case, but I thought it was a piece of the broken 4th gear synchronizer cone.

Poor Merkabah. They really hurt her.

Removed the synchro cone, the 3rd gear and the needle bearing, exposing the underlying race that actually looked not too bad. The definitive opinion would come from Eduardo, but the problem was that it was as stuck to the shaft as every other piece of metal to each other in that pretty pretty gearbox, hmm…

I would have to modify the neo-press-extractor-port-o-power to take out the race and probably the other races still waiting to show up when disassembling the rest of the gear shaft. To do that I needed to go to Verardo’s pile of metal junk and get some steel pieces to play with.

One of the mechanicians approached and took me out of my calculations and mental designing reminding me that the Montero was ready for the final test. After quite a big servicing and the swapping of the transfer case they had it ready to check if the transmission was working properly.

Then, Eduardo and I headed for the hardest climb at hand near San Felipe, and put the Montero under stress. The transmission worked perfectly well, and the old and faithful Japanese performed as the same white spider he used to be before the embarrassing episode on the ditch at the countryside.

Eduardo could not resist to make a video, even if it was not the hardest part of the trail. The 4x4 looks good, though.

When we went back to the shop it was already time to close.

That’s it, for now.

Greetings to you all. Keep the faith.

Pairoa

But, always the big BUT, the jack did not work horizontally, as you probably all knew. Well, I didn’t. So, I had to hang the whole bunch of kilos of metal from the winch and put it vertically, or almost vertically to make the jack work.

It was then just a matter of applying a little pressure on the shaft, only the six millimeters allowed by the play between the gears, change progressively the thickness of the retainers, and eventually the bearing fell soundly on the jack. Took some time, but it worked. Thanks again, brother.

I got the neo-extractor free from the gear box and put the later back on the trolley to keep on with the disassembling.

Removing the shaft with all the gears from the box was relatively easy thanks to the winch and the ropes. Christ, how heavy they are!

Once on the working tray, I made a vain try to take the front bearing out using the extractor. No way, and I knew it. Grabbed the powergrinder and the screwdriver and destroyed the outer bronze cage and took the rollers out with no mercy. I then grinded the inner raceway until it was so thin that a couple of strikes broke it loose. I was pretty afraid of damaging the shaft so it took me quite a while to get to that point.

Once the bearing was out, the locking nut was exposed, another big task in itself. It was pretty clear, again, that the sliding sleeve was freely moving over the synchronizer’s hub as there were no end pieces nor springs at sight.

I will save you from the carnage of the removal of the locking nut, just tell that I finally asked Eduardo to help me to take it out as I was not able to do it without suffering. The chisel work is definitely not for me.

The following was a surprise: I removed the synchronizer hub and found that the cone on the side of the 3rd gear was also broken, in many pieces. I had seen before one of the little broken pieces when first opening the lateral cover of the the gear case, but I thought it was a piece of the broken 4th gear synchronizer cone.

Poor Merkabah. They really hurt her.

Removed the synchro cone, the 3rd gear and the needle bearing, exposing the underlying race that actually looked not too bad. The definitive opinion would come from Eduardo, but the problem was that it was as stuck to the shaft as every other piece of metal to each other in that pretty pretty gearbox, hmm…

I would have to modify the neo-press-extractor-port-o-power to take out the race and probably the other races still waiting to show up when disassembling the rest of the gear shaft. To do that I needed to go to Verardo’s pile of metal junk and get some steel pieces to play with.

One of the mechanicians approached and took me out of my calculations and mental designing reminding me that the Montero was ready for the final test. After quite a big servicing and the swapping of the transfer case they had it ready to check if the transmission was working properly.

Then, Eduardo and I headed for the hardest climb at hand near San Felipe, and put the Montero under stress. The transmission worked perfectly well, and the old and faithful Japanese performed as the same white spider he used to be before the embarrassing episode on the ditch at the countryside.

Eduardo could not resist to make a video, even if it was not the hardest part of the trail. The 4x4 looks good, though.

When we went back to the shop it was already time to close.

That’s it, for now.

Greetings to you all. Keep the faith.

Pairoa

Re: Mercedes 2626 AK 6x6

This is indeed quite tricky, if the disc is not exactly lined up, you'll end up with the gearbox not fitting.pairospam hat geschrieben: ↑2020-05-14 3:17:45Then I put the adapter flywheel back on and adjusted the disc position with a steel strut, by eye only, trusting it would be a just one-time maneuver.

171125.jpg

And it was. The intermediate shaft went in a perfectly centered clutch disc and the bell housing was secured with the many bloody bolts, with the appropriate torque, of course.

When we had the gearbox of my LP out for clutch replacement we had nothing as a reference and we had the primary drive taken out for line up. Since the gearbox was also disassembled is was easy to do and once the clutch plate was lined up we placed the primary shaft back in the gearbox. Assembly was easy.

Mein blogs: http://rundhauber.eu/ und http://lp2223.com

Re: Mercedes 2626 AK 6x6

a90:

Hello and yes, I remembered pretty well how tricky it was the first time, ending up in steel porno, but I definitely wanted not to disassemble any more of the bell housing or whatever.

Life, God, the engine... everything seemed to be cooperating this time. Why should it be so difficult? Just went on, with trust.

Cheers.

Pairoa

Hello and yes, I remembered pretty well how tricky it was the first time, ending up in steel porno, but I definitely wanted not to disassemble any more of the bell housing or whatever.

Life, God, the engine... everything seemed to be cooperating this time. Why should it be so difficult? Just went on, with trust.

Cheers.

Pairoa

Re: Mercedes 2626 AK 6x6

Hi:

Time for an update though you might know that, times being, I have not made great progresses.

The big challenge of the last weeks had been, of course, the disassembling of the Zahnradfabrik Friedrichshafen 5 S-110 GPA bloody gearbox which resulted in the PITA everyone, except me, expected.

Trying to take out the 3rd gear from the shaft using the big extractor was a waste of time and a dangerous exercise. I could not use the hydraulic press of the workshop because it was blocked far away surrounded by cars and the shaft was heavy as hell, no way to take it there without the portable winch.

So, I got some pieces of scrapped steel plates from Verardo’s machineshop, cut and adapted them to go in between the gears and thus allow the compact neo-press to apply pressure properly without damaging the components.

I welded lateral reinforcements to strengthen the plates though I was terrified by the idea of some incandescent piece of molten steel going directly in between the gears and the bearings, no matter how far the shaft was from the welding place. So, I wrapped the shaft in a thick cocoon of paper and plastic. Too much?

Anyway, it worked, the press. The 3rd gear went out with not much pain and the synchronizer hub for the 1st and 2nd gears was exposed. Good.

Next, the borrowed extractor was the best tool for removing the hub in this case and then the synchronizer ring and the 1st gear could be easily removed on their turn.

Each time I took a race or a gear out was like winning a little battle, and though it may look easy and fast it was not.

Time for an update though you might know that, times being, I have not made great progresses.

The big challenge of the last weeks had been, of course, the disassembling of the Zahnradfabrik Friedrichshafen 5 S-110 GPA bloody gearbox which resulted in the PITA everyone, except me, expected.

Trying to take out the 3rd gear from the shaft using the big extractor was a waste of time and a dangerous exercise. I could not use the hydraulic press of the workshop because it was blocked far away surrounded by cars and the shaft was heavy as hell, no way to take it there without the portable winch.

So, I got some pieces of scrapped steel plates from Verardo’s machineshop, cut and adapted them to go in between the gears and thus allow the compact neo-press to apply pressure properly without damaging the components.

I welded lateral reinforcements to strengthen the plates though I was terrified by the idea of some incandescent piece of molten steel going directly in between the gears and the bearings, no matter how far the shaft was from the welding place. So, I wrapped the shaft in a thick cocoon of paper and plastic. Too much?

Anyway, it worked, the press. The 3rd gear went out with not much pain and the synchronizer hub for the 1st and 2nd gears was exposed. Good.

Next, the borrowed extractor was the best tool for removing the hub in this case and then the synchronizer ring and the 1st gear could be easily removed on their turn.

Each time I took a race or a gear out was like winning a little battle, and though it may look easy and fast it was not.

Re: Mercedes 2626 AK 6x6

When the only gears remaining were the reverse and the slow 1st ones, it felt pretty releaving. I turned the shaft around and took out the reverse gear along with the synchronizer ring, paying much attention to the tiny steel bearing balls that served as stoppers for the sliding synchronizer ring. If I loosed them I surely would be in trouble.

Made an attempt to remove the big 1st slow gear but it seemed to be a little more difficult than the others. I checked the manual and realized that it had to be taken out from the opposite side of the shaft. It was hard to see at naked eye the edge of the lip on the shaft. Ops. Beware of enthousiasm, Pairoa!

I laughed at myself and I left, leaving the steel pieces and tools as they were. It was late and had been manipulating the shaft, the press and the winch the whole afternoon and my back warned me about keeping up that way. I was happy, though.

Next Sunday morning I went out with the dogs only for a shorter walk, as my back actually needed some rest.

The nice and fresh avenue where we live, full of trees and well kept grass, was being torn apart in the name of progress. It would become a beautiful four lane highway with a nice central array of street lamp posts, with no place for trees. Christ.

I was really happy with the idea of leaving the city soon.

When back at the shop, the shaft was too long for using the neo-press, but there was not problem then for using the traditional hydraulic press, and the shaft was light enough to take it there by hand. Good.

After a few moves, the shaft was finally naked and all the components were ready for inspection, cleaning and, eventually, replacement.

I had already bought all the bearings, some of the sliding synchronizer rings and rings, but I still was waiting for those that had been bought abroad. There was not much to do but to wait for the courier companies and the post to deliver.

I am extremely grateful to all the friends that helped with the search and the delivery of the parts, thank you guys.

The past Sunday morning I finally felt good enough for resuming the run with the dogs. The poplars were naked, once again in time, and the dogs had fun with the cushion of fallen leaves. There was frost in the shade of the trees, though the air was warmer than expected at that time of the morning. Weather is completely crazy, as constantly remarked, and it seems that it has absolutely no intention to change.

I came back home sweating like a cow but happy, with no pain at all. Finished the stretching routine, went for a shower and then took the pickup out to go to the countryside and, suddenly, the dogs went crazy.

It was a little abandoned dog, skinny and so scared that it hurt just seeing her wandering out. She saw me and came directly to me and asked for help standing on her hind legs. Hey! - I said to her - We are full, can’t you see? Don’t look at me in the eyes like this, please!

Closed my eyes and got into the pickup. It really hurt. One minute later, though, Carmen went out of the house… and saw the dog. The rest is history.

Introducing Hooka, the new arrived to Pairoa’s foster home for helpless dogs.

She was immediately accepted by all the crew, ate like she had not eaten for years and stopped shaking only late in the afternoon. She slept for eight hours non stop. I think she was at ease for the first time in quite a long period of suffering and fear.

Greatings to you all. Help if you can. And, even better, when you can’t.

Pairoa

Made an attempt to remove the big 1st slow gear but it seemed to be a little more difficult than the others. I checked the manual and realized that it had to be taken out from the opposite side of the shaft. It was hard to see at naked eye the edge of the lip on the shaft. Ops. Beware of enthousiasm, Pairoa!

I laughed at myself and I left, leaving the steel pieces and tools as they were. It was late and had been manipulating the shaft, the press and the winch the whole afternoon and my back warned me about keeping up that way. I was happy, though.

Next Sunday morning I went out with the dogs only for a shorter walk, as my back actually needed some rest.

The nice and fresh avenue where we live, full of trees and well kept grass, was being torn apart in the name of progress. It would become a beautiful four lane highway with a nice central array of street lamp posts, with no place for trees. Christ.

I was really happy with the idea of leaving the city soon.

When back at the shop, the shaft was too long for using the neo-press, but there was not problem then for using the traditional hydraulic press, and the shaft was light enough to take it there by hand. Good.

After a few moves, the shaft was finally naked and all the components were ready for inspection, cleaning and, eventually, replacement.

I had already bought all the bearings, some of the sliding synchronizer rings and rings, but I still was waiting for those that had been bought abroad. There was not much to do but to wait for the courier companies and the post to deliver.

I am extremely grateful to all the friends that helped with the search and the delivery of the parts, thank you guys.

The past Sunday morning I finally felt good enough for resuming the run with the dogs. The poplars were naked, once again in time, and the dogs had fun with the cushion of fallen leaves. There was frost in the shade of the trees, though the air was warmer than expected at that time of the morning. Weather is completely crazy, as constantly remarked, and it seems that it has absolutely no intention to change.

I came back home sweating like a cow but happy, with no pain at all. Finished the stretching routine, went for a shower and then took the pickup out to go to the countryside and, suddenly, the dogs went crazy.

It was a little abandoned dog, skinny and so scared that it hurt just seeing her wandering out. She saw me and came directly to me and asked for help standing on her hind legs. Hey! - I said to her - We are full, can’t you see? Don’t look at me in the eyes like this, please!

Closed my eyes and got into the pickup. It really hurt. One minute later, though, Carmen went out of the house… and saw the dog. The rest is history.

Introducing Hooka, the new arrived to Pairoa’s foster home for helpless dogs.

She was immediately accepted by all the crew, ate like she had not eaten for years and stopped shaking only late in the afternoon. She slept for eight hours non stop. I think she was at ease for the first time in quite a long period of suffering and fear.

Greatings to you all. Help if you can. And, even better, when you can’t.

Pairoa

Re: Mercedes 2626 AK 6x6

Hello:

Things all over the world have become a little crazy, right? Hope it all goes the better way.

Do you remember the NissanTerrano? I had been not able to get rid of her after all this time. She was parked at home, waiting for a definition that never came, until there was no more option. Now I needed the place for the Navara and the Montero so I had to take her out.

When the towing truck came, even Carmen felt a little sad. We would miss her.

Taking her to the countryside was the correct move. She would wait a little at the stable and when my shop-garage was ready I would accommodate her inside and maybe Eduardo and I would make some kind of monstruous electric or atomic 4x4, after finishing the 6x6 Blazer project, of course. Ah… this has no ending.

I found the replacement for the other broken synchronizer ring on a store in Santiago, but the rest of the spares for the gearbox was still trying to make its way through the convulsed customs all around so I was not able of making any more progress on that subject so, as usual, I directed my efforts to the pending stuff.

One particular issue that was still on the to-do-list was the backwards tilting of the cabin. When installed the suspension of the cabin of Spare, the front lifted nearly 9 cm compared with the original rigid suspension but the rear kept at the same level, and thus the cabin tilted backwards permanently, making the Merkabah look awkward and the sitting position a little uncomfortable, especially for Carmen as the butt section of the new seats was also tilted backwards a little.

I was also worried for the tilting because the rear of the cabin may be a little too close to the front wall of the Box.

With the addition of the seats, the dashboard, the insulation and all the stuff inside the cabin, the weight made the front lower a couple of centimeters, but it still was very noticeable. Something had to be made about it.

After some considerations and a little thinking, I thought I found the right way to solve the problem by lifting the rear supports.

At first I wanted to shorten the supports for the shock absorbers, especially when inspected and found that they were not original, though I preferred to make new supports and build supples for the support of the support. Right.

Looked around and gathered some metal scrap pieces to work with. Luckily there still were some.

The goal was to make a couple of shock supports seven centimeters shorter. It was a quite cold afternoon so I put myself to work accompanied by a big cup of almost boiling tea.

I cut the pieces and marked them. I needed to make big holes to allow the shocks go through and fortunately I had at hand the jig saw, the serious one. As the steel was only 5 mm thick it was pretty easy to cut.

The boring phase came next, when using the hand lime to make the rough edges even and to get the circles looking like an actual circle. The result was pretty encouraging but when finished the first one it was already time to go.

Things all over the world have become a little crazy, right? Hope it all goes the better way.

Do you remember the NissanTerrano? I had been not able to get rid of her after all this time. She was parked at home, waiting for a definition that never came, until there was no more option. Now I needed the place for the Navara and the Montero so I had to take her out.

When the towing truck came, even Carmen felt a little sad. We would miss her.

Taking her to the countryside was the correct move. She would wait a little at the stable and when my shop-garage was ready I would accommodate her inside and maybe Eduardo and I would make some kind of monstruous electric or atomic 4x4, after finishing the 6x6 Blazer project, of course. Ah… this has no ending.

I found the replacement for the other broken synchronizer ring on a store in Santiago, but the rest of the spares for the gearbox was still trying to make its way through the convulsed customs all around so I was not able of making any more progress on that subject so, as usual, I directed my efforts to the pending stuff.

One particular issue that was still on the to-do-list was the backwards tilting of the cabin. When installed the suspension of the cabin of Spare, the front lifted nearly 9 cm compared with the original rigid suspension but the rear kept at the same level, and thus the cabin tilted backwards permanently, making the Merkabah look awkward and the sitting position a little uncomfortable, especially for Carmen as the butt section of the new seats was also tilted backwards a little.

I was also worried for the tilting because the rear of the cabin may be a little too close to the front wall of the Box.

With the addition of the seats, the dashboard, the insulation and all the stuff inside the cabin, the weight made the front lower a couple of centimeters, but it still was very noticeable. Something had to be made about it.

After some considerations and a little thinking, I thought I found the right way to solve the problem by lifting the rear supports.

At first I wanted to shorten the supports for the shock absorbers, especially when inspected and found that they were not original, though I preferred to make new supports and build supples for the support of the support. Right.

Looked around and gathered some metal scrap pieces to work with. Luckily there still were some.

The goal was to make a couple of shock supports seven centimeters shorter. It was a quite cold afternoon so I put myself to work accompanied by a big cup of almost boiling tea.

I cut the pieces and marked them. I needed to make big holes to allow the shocks go through and fortunately I had at hand the jig saw, the serious one. As the steel was only 5 mm thick it was pretty easy to cut.

The boring phase came next, when using the hand lime to make the rough edges even and to get the circles looking like an actual circle. The result was pretty encouraging but when finished the first one it was already time to go.

Re: Mercedes 2626 AK 6x6

The next day was pretty cold too, so I left on purpose the die grinder at home and kept up with the limes for finishing the pieces. Time was not an issue and a little physical effort was okay for fighting the cold.

While I was working with the lime I repeated myself that it was useless to work so hard to make the holes perfectly round. Who cares? You will weld it, it will be hidden forever, dude. Though, I made my best efforts to get perfect circles in the steel. Yes… I know.

Finished the holes, cut and grinded the flat pieces and then cut a couple of cylindric pieces to complete the supports. Then, I got the MIG welder and assembled it all.

I think it came out pretty well, pretty tough and with the right length to keep the cabin even, or so I hoped.

Next, I got a piece of rectangular steel profile to make the supples for the supports of the coil springs. I needed 7 centimeters to fit so steel strips supples were added as well.

Up to that point, no problems, just a lot of drilling, cutting and grinding with the lime. Then, I tried the new parts in situ. Hmm…

The arc described by the rear of the cabin when tilting made the raised tip of the shock absorber to go out of center, by far, and there was no way that it could work like that, even if there was some little play available. Ops.

Gave it a little thought and decided to tilt a little the supple and see if I could use the tolerance of the mounting to compensate for the inclined plane the shocks would work under the new situation.

Cut out a piece of the recently added supple of the supple, forced it to a carefully optical and mathematically studied angle and made a try. It looked like it could work.

It was really a PITA having to make it all again, particularly the part of cutting and regularize the damn holes, and taking the decision was not as easy as it seems. Anyway, it was not the worst thing that had happened so far so I grabbed the rest of the material I needed and put myself at work, again.

For the sake of easiness in building I changed the round bottom mount for a squared one, and changed the orientation of the lower mounting in order to make the shock pivot, though slightly, in the correct sense.

While I was working with the lime I repeated myself that it was useless to work so hard to make the holes perfectly round. Who cares? You will weld it, it will be hidden forever, dude. Though, I made my best efforts to get perfect circles in the steel. Yes… I know.

Finished the holes, cut and grinded the flat pieces and then cut a couple of cylindric pieces to complete the supports. Then, I got the MIG welder and assembled it all.

I think it came out pretty well, pretty tough and with the right length to keep the cabin even, or so I hoped.

Next, I got a piece of rectangular steel profile to make the supples for the supports of the coil springs. I needed 7 centimeters to fit so steel strips supples were added as well.

Up to that point, no problems, just a lot of drilling, cutting and grinding with the lime. Then, I tried the new parts in situ. Hmm…

The arc described by the rear of the cabin when tilting made the raised tip of the shock absorber to go out of center, by far, and there was no way that it could work like that, even if there was some little play available. Ops.

Gave it a little thought and decided to tilt a little the supple and see if I could use the tolerance of the mounting to compensate for the inclined plane the shocks would work under the new situation.

Cut out a piece of the recently added supple of the supple, forced it to a carefully optical and mathematically studied angle and made a try. It looked like it could work.

It was really a PITA having to make it all again, particularly the part of cutting and regularize the damn holes, and taking the decision was not as easy as it seems. Anyway, it was not the worst thing that had happened so far so I grabbed the rest of the material I needed and put myself at work, again.

For the sake of easiness in building I changed the round bottom mount for a squared one, and changed the orientation of the lower mounting in order to make the shock pivot, though slightly, in the correct sense.

Re: Mercedes 2626 AK 6x6

This time I brang the die grinder to the shop and I worked both with it and with the lime to speed up the process. It was not much faster, though.

Of course, the supples for the supports were both prepared, cut, welded and even flattened out to make them even.

Evolutionary lane.

When the new pieces were ready I assembled one of the the mountings and checked if it worked, and it did pretty well. It was quite annoying to assemble the whole thing because of the tiny spaces to put fingers and wrenches on though, all in all, I was happy.

That Saturday morning the reborn red Ford Cargo was ready to go for a serious test ride, and Eduardo and I gathered at the shop early to take it out.

It looked pretty good, especially when remembering its poor state before renovation.

Unfortunately, when Eduardo was taking back into the shop the little Fiorino, recently renewed too, going backwards, the door suddenly got open loose just passing in front of the Merkabah. Ops.

The shiny Italian sportive pickup was no competitor for the big german truck and, steel against steel, there was no doubt about which one sustained more damage. Actually, the roller of the front winch and the bumper of the Merkabah did not even noticed the strike.

Shit happens, and even if there is some feeling behind every car or truck you take care of, it is just steel, plastic and paint. So, we shrugged, took all the cars back into the shop and headed for the countryside in the roaring Ford Cargo.

Surprisingly, it was very quiet comparing with the Merkabah, even if there was still some work to do on thermal and sound proofing. Or was the Merkabah too noisy?

Anyway, we made our way through a heavy traffic despite the restrictive measures and the engine behave pretty good. Eduardo did a very good job, as always.

At the construction site in the country, we used the crane to help with the build of the roof of the new barn/garage/shop. Ramón, the builder, was happy with the aid that saved him a lot of time and efforts.

Eduardo maneuvered the crane with growing skills and was on his turn pretty happy with the truck: We have a new toy, Pairoa!

Of course, the supples for the supports were both prepared, cut, welded and even flattened out to make them even.

Evolutionary lane.

When the new pieces were ready I assembled one of the the mountings and checked if it worked, and it did pretty well. It was quite annoying to assemble the whole thing because of the tiny spaces to put fingers and wrenches on though, all in all, I was happy.

That Saturday morning the reborn red Ford Cargo was ready to go for a serious test ride, and Eduardo and I gathered at the shop early to take it out.

It looked pretty good, especially when remembering its poor state before renovation.

Unfortunately, when Eduardo was taking back into the shop the little Fiorino, recently renewed too, going backwards, the door suddenly got open loose just passing in front of the Merkabah. Ops.

The shiny Italian sportive pickup was no competitor for the big german truck and, steel against steel, there was no doubt about which one sustained more damage. Actually, the roller of the front winch and the bumper of the Merkabah did not even noticed the strike.

Shit happens, and even if there is some feeling behind every car or truck you take care of, it is just steel, plastic and paint. So, we shrugged, took all the cars back into the shop and headed for the countryside in the roaring Ford Cargo.

Surprisingly, it was very quiet comparing with the Merkabah, even if there was still some work to do on thermal and sound proofing. Or was the Merkabah too noisy?

Anyway, we made our way through a heavy traffic despite the restrictive measures and the engine behave pretty good. Eduardo did a very good job, as always.

At the construction site in the country, we used the crane to help with the build of the roof of the new barn/garage/shop. Ramón, the builder, was happy with the aid that saved him a lot of time and efforts.

Eduardo maneuvered the crane with growing skills and was on his turn pretty happy with the truck: We have a new toy, Pairoa!

Re: Mercedes 2626 AK 6x6

Back at the shop, monday afternoon, I gathered all the pieces, again, gave them a final retouch and reinforced the supples with a lateral vertical plate. It gave excellent resistance but made the assembly even more complicated, though.

As the weather was pretty cold and the painting chamber was occupied with another truck, I decided to assemble the supports and the shocks and leave them on until the conditions were more propitious.

Once both rear supports were in place, I measured the gap that I was waiting to find between the two portions of the mudguard, and it was bigger than expected: 8,5 instead of 7 centimeters. That difference made the cabin tilt frontwards slightly but noticeably, though I was sure that the height would diminish when the truck started to move and the coil springs settled, hopefully the same amount required to make the cabin even with the horizontal (yellow line on the picture).

Opened the door of the passenger side to see if moving and jumping inside the cabin would lower the gap, but it was very noisy and the door was stiff. I inspected the sliding piece and realized that the superior hinge was loose. Ops.

I once suspected that I had not tightened the bolts of the hinge, back in time, just after putting the inner lining of the door, and I left the job for later, when the inner sealing gasket was available and had no more option but to take the lining out.

Well… the lining went out, and despite being careful a couple of plastic pins broke and other went loose from the old and desilusioned lining.

I adjusted the door, making it fit better than before, and tightened the hinges. Went out to buy some more plastic pins and applied some glue to try to repair the holes in the wooden panel of the lining. It was late when I finished and so I left the lining and the glue out to dry up.

Next morning the first thing I did was to put the lining back on the door, even before saying hello to the people of the shop. Good. No harm.

Went up into the cabin and moved and jumped inside, with no effect on the rear height. Then I pulled the lever to open the door from the inside but the mechanism was not working. It was perfect before. Plop.

This is car renovation: you fix something and something else brakes.

I needed to take the lining out again, so I left it like that until it was absolutely necessary to do it. Not on the mood.

Well, the next couple of hours I dedicated myself to clean up and to make order around, below and above the Merkabah. It was, again, saturated of metal grit, dust, dog hair, pieces of carboard and paper, spares, scrap pieces and a long etcetera.

I was at it when I tumbled on a piece that I had left for missing some time ago: the towing pin. It was the original one, bought from a crippy guy, do not remember when.

It was better to do something before loosing it again, so I drilled a hole on the handle and grabbed a piece of chain. I wanted to chain the pin to the frame to avoid it to be stolen, though I found the chain a little bulky, hmm…

Thought about fixing the pin with a cable instead, lighter and quieter, so I searched among the trash of the workshop for discarded clutch cables and found the one I was looking for. It came even with a plastic sheath, perfect.

Eduardo came by and reminded me that anybody with a cheap wire cutter could come and get away with the pin and with my most elegant cable arrangement.

So, chain it was.

Later, I finished to make order and stayed a moment at staring the truck. The thoughts on how overlanding travelling had become progressively more difficult inevitably struck me.

All kinds of travelling were in jake, actually, and it would probably not get any better as the local and global economical-political situation got worse every day.

Anyway, as a man in faith I left things in wiser hands and took a deep cold breath. More than probably there was a good reason for all of this, and for all the time spent in preparing the truck so far and, of course, for all the time and trouble that was still ahead before completion of the project.

Did I ever mention that I really like autumn colors?

Greetings.

Pairoa

As the weather was pretty cold and the painting chamber was occupied with another truck, I decided to assemble the supports and the shocks and leave them on until the conditions were more propitious.

Once both rear supports were in place, I measured the gap that I was waiting to find between the two portions of the mudguard, and it was bigger than expected: 8,5 instead of 7 centimeters. That difference made the cabin tilt frontwards slightly but noticeably, though I was sure that the height would diminish when the truck started to move and the coil springs settled, hopefully the same amount required to make the cabin even with the horizontal (yellow line on the picture).

Opened the door of the passenger side to see if moving and jumping inside the cabin would lower the gap, but it was very noisy and the door was stiff. I inspected the sliding piece and realized that the superior hinge was loose. Ops.

I once suspected that I had not tightened the bolts of the hinge, back in time, just after putting the inner lining of the door, and I left the job for later, when the inner sealing gasket was available and had no more option but to take the lining out.

Well… the lining went out, and despite being careful a couple of plastic pins broke and other went loose from the old and desilusioned lining.

I adjusted the door, making it fit better than before, and tightened the hinges. Went out to buy some more plastic pins and applied some glue to try to repair the holes in the wooden panel of the lining. It was late when I finished and so I left the lining and the glue out to dry up.

Next morning the first thing I did was to put the lining back on the door, even before saying hello to the people of the shop. Good. No harm.

Went up into the cabin and moved and jumped inside, with no effect on the rear height. Then I pulled the lever to open the door from the inside but the mechanism was not working. It was perfect before. Plop.

This is car renovation: you fix something and something else brakes.

I needed to take the lining out again, so I left it like that until it was absolutely necessary to do it. Not on the mood.

Well, the next couple of hours I dedicated myself to clean up and to make order around, below and above the Merkabah. It was, again, saturated of metal grit, dust, dog hair, pieces of carboard and paper, spares, scrap pieces and a long etcetera.

I was at it when I tumbled on a piece that I had left for missing some time ago: the towing pin. It was the original one, bought from a crippy guy, do not remember when.

It was better to do something before loosing it again, so I drilled a hole on the handle and grabbed a piece of chain. I wanted to chain the pin to the frame to avoid it to be stolen, though I found the chain a little bulky, hmm…

Thought about fixing the pin with a cable instead, lighter and quieter, so I searched among the trash of the workshop for discarded clutch cables and found the one I was looking for. It came even with a plastic sheath, perfect.

Eduardo came by and reminded me that anybody with a cheap wire cutter could come and get away with the pin and with my most elegant cable arrangement.

So, chain it was.

Later, I finished to make order and stayed a moment at staring the truck. The thoughts on how overlanding travelling had become progressively more difficult inevitably struck me.

All kinds of travelling were in jake, actually, and it would probably not get any better as the local and global economical-political situation got worse every day.

Anyway, as a man in faith I left things in wiser hands and took a deep cold breath. More than probably there was a good reason for all of this, and for all the time spent in preparing the truck so far and, of course, for all the time and trouble that was still ahead before completion of the project.

Did I ever mention that I really like autumn colors?

Greetings.

Pairoa

Re: Mercedes 2626 AK 6x6

Hello everyone:

Life goes on, corona-damn-virus or not. I see from other threads that there is a lot of people working on their projects and keeping up as they can with their lives and their routines. Good.

Seems that the world had come to a sudden stop, and the parcel with the parts for the gearbox had been returned to the sender at least twice so far, before even reaching the German customs.

In the meantime, I went on around trying to resolve the details that were left for an uncertain tomorrow after.

The upper piece of the snorkel was lying still on a couple of dusty boxes since quite a while. Eddie did not touch it and only restored the bigger lower part, so it would be my own job to get the tube back to its purposedly life.

It was a very robust piece and had so far withstand a couple of drops without any major damage. I put it in place and seemed that it all fitted pretty well, even if I could not find the ad hoc bracket.

The problem was the prefilter box that went mounted on the waterspout, whose actual name eludes me. It was in a very precarious state, beyond any possible recovery. It came from a scrapped truck from far in the deep south, and of course it was not the original part.

So, having time and plenty of energy to do it, I decided to build a new one myself.

I looked around but there was not a single piece of steel sheet left to work with so I went to Verardo’s workshop and got some more material from the scrap pile.

The difficult part of making round sized objets with steel sheets is, of course, shaping the metal to get the right curves. I actually was not on the mood to think of building some sort of folding device, I just wanted to shape the sheets and weld the thing right away. Patience was a scarse asset at those moments.

Looked for any tubular object in the workshop, and found an appropriate cylinder sleeve and a couple of empty paint cans that I tacked together with the MIG. Then, I aligned them on a trestle and worked by hand the metal sheet until I got the curve I wanted. Good.

Repeated the same exercise a couple of times with different sizes of cylinders following the sketch of the original, or semi-original, prefilter box. Pian piano the shape of something new began to emerge from the metal. The mechanicians made fun of me saying I was fabricating some sort of stove to fight the cold. Hmm…

I had more time to work at the workshop as my regular work became less demanding on my particular expertise with the spread of the corona-damn-virus so I made progresses faster than expected, but the job of folding and cutting metal sheets is not as fast as one would like. It was fun and demanding, though, right what I needed.

Life goes on, corona-damn-virus or not. I see from other threads that there is a lot of people working on their projects and keeping up as they can with their lives and their routines. Good.

Seems that the world had come to a sudden stop, and the parcel with the parts for the gearbox had been returned to the sender at least twice so far, before even reaching the German customs.

In the meantime, I went on around trying to resolve the details that were left for an uncertain tomorrow after.

The upper piece of the snorkel was lying still on a couple of dusty boxes since quite a while. Eddie did not touch it and only restored the bigger lower part, so it would be my own job to get the tube back to its purposedly life.

It was a very robust piece and had so far withstand a couple of drops without any major damage. I put it in place and seemed that it all fitted pretty well, even if I could not find the ad hoc bracket.

The problem was the prefilter box that went mounted on the waterspout, whose actual name eludes me. It was in a very precarious state, beyond any possible recovery. It came from a scrapped truck from far in the deep south, and of course it was not the original part.

So, having time and plenty of energy to do it, I decided to build a new one myself.

I looked around but there was not a single piece of steel sheet left to work with so I went to Verardo’s workshop and got some more material from the scrap pile.

The difficult part of making round sized objets with steel sheets is, of course, shaping the metal to get the right curves. I actually was not on the mood to think of building some sort of folding device, I just wanted to shape the sheets and weld the thing right away. Patience was a scarse asset at those moments.

Looked for any tubular object in the workshop, and found an appropriate cylinder sleeve and a couple of empty paint cans that I tacked together with the MIG. Then, I aligned them on a trestle and worked by hand the metal sheet until I got the curve I wanted. Good.

Repeated the same exercise a couple of times with different sizes of cylinders following the sketch of the original, or semi-original, prefilter box. Pian piano the shape of something new began to emerge from the metal. The mechanicians made fun of me saying I was fabricating some sort of stove to fight the cold. Hmm…

I had more time to work at the workshop as my regular work became less demanding on my particular expertise with the spread of the corona-damn-virus so I made progresses faster than expected, but the job of folding and cutting metal sheets is not as fast as one would like. It was fun and demanding, though, right what I needed.

Re: Mercedes 2626 AK 6x6

Something wonderful happened those days, though, something pretty rare and most expected in San Felipe: it rained.

After almost a year with not a single chrystal of snow up on the Andes range, you could see white on the mountains. Perhaps you cannot appreciate the importance of this, but for this dry place the presence of snow is paramount, even a small amount of it. It was good news among the current disaster.

Verardo offered me a piece of a very appealing inox filter sheet to complete the box/stove, but I had to wait for the moment he will cut it to fabricate whatever he needed to fabricate.

One almost forgotten piece of the rear wall of the cabin of the Merkabah that was cut out when opening the pass-through was the donor of some more thick material to work with. Every piece of scrap, as usual, may become pretty usefull, and you do not know when you might need it.

I went on cutting, curving and welding metal until I had no choice but to wait for the promised inox piece.

There was a clear and present threat that there would probably be a lockdown that included our region, a desperate and counterproductive action necessary to manage stupid people that do not observe minimal directives to watch out for their own health.

Anyway, as I probably would not get too far with the prefilter box of the snorkel I preferred to give a hand to Eduardo. He decided to restore the bed of the Ford and I helped him to replace the side members for some more robust ones and to replace the rusted and ugly dented rear fender as well as to repair and reinforce some spots.

I cut and shaped the metal pieces and prepared them while he was charged of welding them with the arc welder. I was so used to the MIG that working with the electrodes and the arc was not my favourite job.

Those evenings we were given nice views of the sunsets, some of them pretty spectacular. They were there for free but, naturally, not too many appreciated them, prisoners of their own hurries and fears.

We worked until late but did not get to finish the job. Next day, yesterday to be precise, we continued where we left it and I cut a couple of large and heavy pieces of iron sheet for the rear end of the bed and welded them together using the MIG. A different stuff, of course.

Earlier, I firstly had decided to build a mobile bridge crane, like the one I used to borrow, to keep it permanently in the new garage/shed in the countryside, but when aiding to build the roof with the crane of the Ford I got convinced that it was far better to install a medium sized overhead bridge crane instead.

After discussing the idea with the builder and with Verardo, who knows a lot about steel, and do the maths, I ordered some profiles and some pieces to be cut to build the trolley and mount the crane. Verardo ordered the profiles for me, with a little discount, of course.

It was getting late so we tack welded the rear plate of the bed and went to Verardo’s machineshop and loaded the brand new iron profiles along with a couple of steel beams that I had bought a couple of years ago when I had the idea of building a massive rigid overchassis to install the living Box on. They were a little rusted, but they will be worked out so they would become the shiny bridge girder of the crane.

Back at the shop Eduardo got the welder and went on with the welding of the rear plate of the bed, consuming lots and lots of electrodes. I was waiting for him to finish to grind and make the final retouches, but it was already time to go home when he completed the job.

We made order, well… some kind of order, and we all left. It was the last achievement before the complete lockdown.

Everything is in suspense now, except my watches, of course.

Hope everyone is okay.

Pairoa

After almost a year with not a single chrystal of snow up on the Andes range, you could see white on the mountains. Perhaps you cannot appreciate the importance of this, but for this dry place the presence of snow is paramount, even a small amount of it. It was good news among the current disaster.

Verardo offered me a piece of a very appealing inox filter sheet to complete the box/stove, but I had to wait for the moment he will cut it to fabricate whatever he needed to fabricate.

One almost forgotten piece of the rear wall of the cabin of the Merkabah that was cut out when opening the pass-through was the donor of some more thick material to work with. Every piece of scrap, as usual, may become pretty usefull, and you do not know when you might need it.

I went on cutting, curving and welding metal until I had no choice but to wait for the promised inox piece.

There was a clear and present threat that there would probably be a lockdown that included our region, a desperate and counterproductive action necessary to manage stupid people that do not observe minimal directives to watch out for their own health.

Anyway, as I probably would not get too far with the prefilter box of the snorkel I preferred to give a hand to Eduardo. He decided to restore the bed of the Ford and I helped him to replace the side members for some more robust ones and to replace the rusted and ugly dented rear fender as well as to repair and reinforce some spots.

I cut and shaped the metal pieces and prepared them while he was charged of welding them with the arc welder. I was so used to the MIG that working with the electrodes and the arc was not my favourite job.

Those evenings we were given nice views of the sunsets, some of them pretty spectacular. They were there for free but, naturally, not too many appreciated them, prisoners of their own hurries and fears.

We worked until late but did not get to finish the job. Next day, yesterday to be precise, we continued where we left it and I cut a couple of large and heavy pieces of iron sheet for the rear end of the bed and welded them together using the MIG. A different stuff, of course.

Earlier, I firstly had decided to build a mobile bridge crane, like the one I used to borrow, to keep it permanently in the new garage/shed in the countryside, but when aiding to build the roof with the crane of the Ford I got convinced that it was far better to install a medium sized overhead bridge crane instead.

After discussing the idea with the builder and with Verardo, who knows a lot about steel, and do the maths, I ordered some profiles and some pieces to be cut to build the trolley and mount the crane. Verardo ordered the profiles for me, with a little discount, of course.

It was getting late so we tack welded the rear plate of the bed and went to Verardo’s machineshop and loaded the brand new iron profiles along with a couple of steel beams that I had bought a couple of years ago when I had the idea of building a massive rigid overchassis to install the living Box on. They were a little rusted, but they will be worked out so they would become the shiny bridge girder of the crane.

Back at the shop Eduardo got the welder and went on with the welding of the rear plate of the bed, consuming lots and lots of electrodes. I was waiting for him to finish to grind and make the final retouches, but it was already time to go home when he completed the job.

We made order, well… some kind of order, and we all left. It was the last achievement before the complete lockdown.

Everything is in suspense now, except my watches, of course.

Hope everyone is okay.

Pairoa

Re: Mercedes 2626 AK 6x6

Dear Pairao,

I follow your article since long and I always love the mix of "truck work" and "beautiful landscape"... and always thinking positive

Its amazing how long you are working on the truck, not giving up... it became a very nice truck

all the best... keep on

Holger

I follow your article since long and I always love the mix of "truck work" and "beautiful landscape"... and always thinking positive

Its amazing how long you are working on the truck, not giving up... it became a very nice truck

all the best... keep on

Holger

-------------------------------------------------------

http://RAL3000-EXMO.de

MAN KAT1 4x4 / FM2

MAN KAT1 6x6 / Abrollkipper

http://RAL3000-EXMO.de

MAN KAT1 4x4 / FM2

MAN KAT1 6x6 / Abrollkipper

Re: Mercedes 2626 AK 6x6

Thank you, Holger. Most appreciated words.

The problem of being in a lockdown, at least for me, is that many new and crazy ideas for the Merkabah come into my mind as there is plenty of time for it to occur. In short I will need a shrink.

Regards from Chile.

Pairoa

The problem of being in a lockdown, at least for me, is that many new and crazy ideas for the Merkabah come into my mind as there is plenty of time for it to occur. In short I will need a shrink.

Regards from Chile.

Pairoa

- Iain_U1250

- neues Mitglied

- Beiträge: 13

- Registriert: 2015-01-21 3:59:16

- Wohnort: Brisbane, Australia

Re: Mercedes 2626 AK 6x6

I am still amazed by you work here Pairo, that gearbox looks like a very hard job to do. The current Covid19 problem has seen us cancel our plans for our round the world trip, we were going to be starting in September, heading to South America. I am guessing it will be a few years before we can hit the road and come and visit you. In the meantime, you will be able to finish your rebuild of that great machine and maybe we can meet up on the road.

Re: Mercedes 2626 AK 6x6

Hi, Iain:

Yes, this infamous and dark issue we and the whole world are in the middle of right now has seen many plans cancelled and dreams broke. I wanted to go to Australia for a bike trip through the desert the next year, and maybe take a lip for a visit. Plop.

The gearbox, actually, is hard but fun to work with. The problem is the lack of proper tools, but to find the way out of every entanglement is a powerful mind driving force.

I really hope that you can start your tour as soon as possible, and we will be waiting for you to come near at any time.

Regards from Chile.

Yes, this infamous and dark issue we and the whole world are in the middle of right now has seen many plans cancelled and dreams broke. I wanted to go to Australia for a bike trip through the desert the next year, and maybe take a lip for a visit. Plop.

The gearbox, actually, is hard but fun to work with. The problem is the lack of proper tools, but to find the way out of every entanglement is a powerful mind driving force.

I really hope that you can start your tour as soon as possible, and we will be waiting for you to come near at any time.

Regards from Chile.

Re: Mercedes 2626 AK 6x6

Hello Pairo, as i mentioned on another site fantastic work and soo close to the next phase of the build. There really is so much more shown on this forum, its just a shame that many of the photoes are not showing in the last3/5th of write up then comes back for last few pages.

I hope that you and the family are all ok and that you tribe of K9 and feline freinds has not grown too much bigger. If u ever do take the trip to Aus you will have to jump accross the pond and visit us in NZ

I hope that you and the family are all ok and that you tribe of K9 and feline freinds has not grown too much bigger. If u ever do take the trip to Aus you will have to jump accross the pond and visit us in NZ

- tooFATtoDRIVE

- Selbstlenker

- Beiträge: 180

- Registriert: 2017-06-16 20:46:29

Re: Mercedes 2626 AK 6x6

Hello Pairoa,

We have not heard from you for a very long time. I hope things are ok at your end. What's the latest with your project?

We have not heard from you for a very long time. I hope things are ok at your end. What's the latest with your project?

Re: Mercedes 2626 AK 6x6

Quite a while, eh?

These have been pretty weird and difficult times for everybody around the world, plenty of fear, anger and frustration, though I have never lost my faith and the feeling that it will all be better in the end. At this point we, the respectful and good people, would all want to kill a politician and a journalist but, instead, we better hang on to our projects and dreams and let the good Boss to give everyone exactly what he deserves.

And so, we go on.

The work on the Merkabah has reached its minimum momentum ever during the last few months, waiting for the spares for the gearbox to arrive.

As I wanted to finish the prefilter box or particle separator, whatever its name may be, I got a discarded filter element of some old truck and cut a piece out of it and made the grill up from the metallic sheet. Maybe it was thinner than optimal but I was not keen on wandering out looking for the perfect piece.

With the front grill in place, I was able to weld and close the box. It looked okay, not perfect of course, but it was okay for the times and the mood being. It needed some more work, though, and the restrictions due to the f…ing “pandemic” prevented more people to come to the shop so I decided to do the plaster and the paint job myself. How hard could it be?

And, actually, it was pretty fun. I had not worked with plaster seriously before, leaving it all to Eddie and then to Joaquin, both of whom make a living of it. It was a little piece, of course, and so it was quite easy and pretty useful for perfectioning the technique.

Once the prefilter box was ready I grabbed the upper part of the snorkel and began to prepare it for the same treatment, as Eddie did with the big lower piece some time ago.

After a few sessions of grinding, plastering, grinding and plastering again, and more grinding, I was happy enough to give both pieces a few hands of primer and more fine grinding.

In the meantime, I was trying to have the new garage for the Merkabah ready at the countryside, with not big success so far.

The building of the new house had taken more than a year due to many problems and delays, and it is still not finished as I write this. We moved in just a moth ago and we have arranged things and ourselves to make our new home liveable without the kitchen furniture and a lot of other important items that still have to be built and installed but, all in all, it has been great so far.

The canine crew grew by three, with one new dog rescued from the streets and two other pretty nice and gentle ones that lived in the neighborhood and fell in love with us and viceversa during the building. You can count them by 13.

The cats are now “only” four.

The big difference, though, is that just the oldest and smallest two dogs and the cats are allowed indoors, and the rest of the dogs are kept outside. They have plenty of space and they look and feel pretty happy, all of them.