My life admits only a few hours to dedicate to the project these times, but something has been done.

Next time I could work at the shop I finished the cap for the filter, with some problems with the welding the thin grille. Anyway, it came out pretty nice and hopefully would work as predicted.

That week I could not be able to work on the frame, again; I had many things to do, places to go to, regular and extra work, etc. It was too hot to think about continuing with the removal of the paint of the cabin that afternoon so I profited of the creative mood and thought about to work out the front winch installation

I took out one of the winches from its original box, or what was left of it, and measured it all again. The idea was to build a compact box around the winch and bolt it hanging under the front crossmember, the more compact the arrangement the better, not to compromise too much the angle of approach. Considering the position of the radiator, some centimeters behind the crossmember, there should be enough space to hide the winch behind the fender, at least partially.

It was pretty useful to have the front crossmember of Spare to play with a little and to help for the measuring of the different components of the future winch support.

It seemed a good idea to make a mockup of the support/container with carton board to figure how things would look like and fit, and that’s what I did. The superior plate would be bent to follow the form of the cross member to which it would be bolted. The compactness would confere strength to the structure. The inferior and frontal plates would be one-piece mounted on hinges on the rear for easier maintenance and removal/installation of the winch.

With such an arrangement there was enough space left between the baseplate and the radiator. I was only concerned about the strength of the whole construct. I thought that a baseplate of 6 mm was a little weaky for a 20.000 lb winch, but that was what the manual said. Anyway, the mockup showed also that the front bumper plate would be intervened minimally to expose the protruding control box and the engage/disengage lever of the winch. The angle of approach would not be critically compromised. All in all, not bad.

Another day of monstruous heat came, and I thought that I was surely making some mistake, peeling off the cabin with the torch. I went to the basics, as it is always pretty helpful. What did I need if I wanted to remove the paint? A car paint remover, of course. At the car paint shop I asked the seller for a good one and he sold me a spray can for a few euros. I made a little test and waited the 10 minutes the instructions recommended. Nothing happened. I sprayed almost the whole the cabin and let it soak for one hour. It worked, but not as magically as I would have wanted. Anyway, it was far better than applying heat and it let me work on other things while waiting for the remover to act.

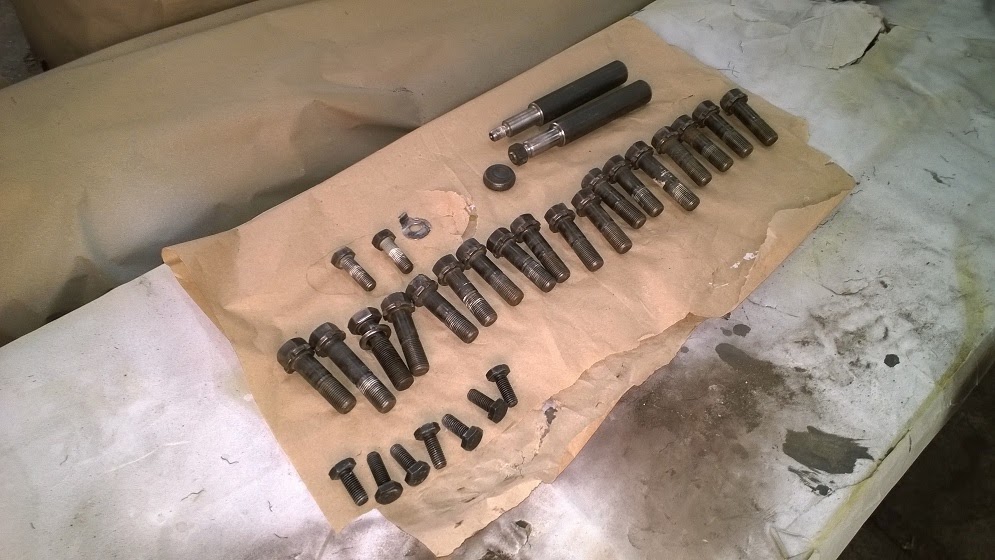

The installation of the front winch was something pretty interesting and I still had not enough time to submerge me in the grit blasting of the frame for many days, so I went to Verardo’s to collect some pieces to build the case and the framing. I bought him a piece of steel plate of 6 mm and got some profiles and tubes from the pile of scrap.

That afternoon we made something unusual and went to Santiago to have dinner with René and Karen Larraguibel, the travellers that had to make a pause in their long term expedition to the Americas because René’s new hotel required of his presence, and they were there for a few hours. We gathered also with Veronica and Nigel, another infected with the expedition truck disease. He is as the moment in the middle of a long term restoration/build of a F-350 based 4x4 camper, with as much attention to detail as myself, if not more.

It was a delicious sushi and a splendid evening.

Alternating between the steel and the cabin in the suffocating heat of the afternoon of San Felipe I was slowly making some progress and continued to remove the paint, piecemeal.

[/img]

[/img]