Hi, again.

El Capitan: I hold on to your little chance. Thanks for the trust.

Busbart: there is a lot of spareparts around for MB trucks, and from many origins; the trouble is that this truck in particular comes directly from germany and it has some peculiar specifications for the european market quiet difficult to match, but I hope that every sparepart needed will be found.

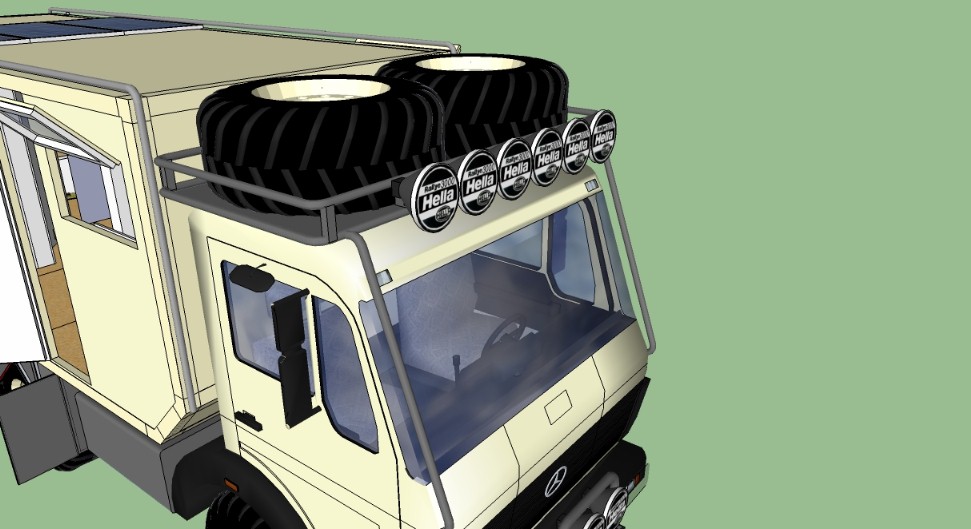

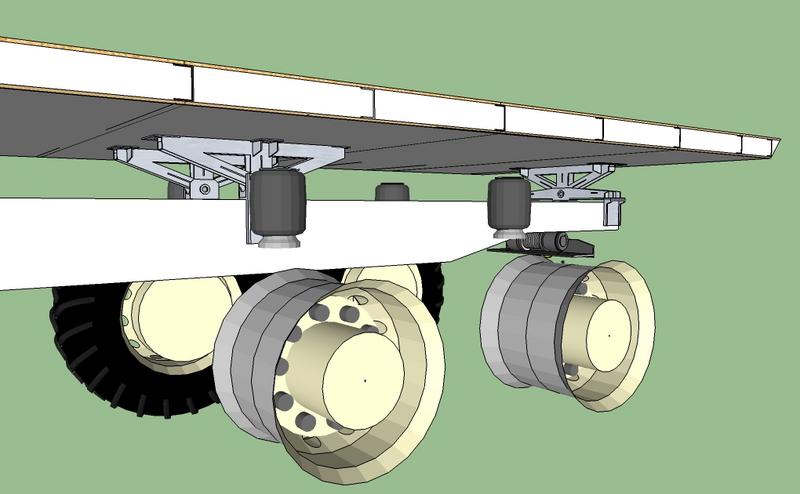

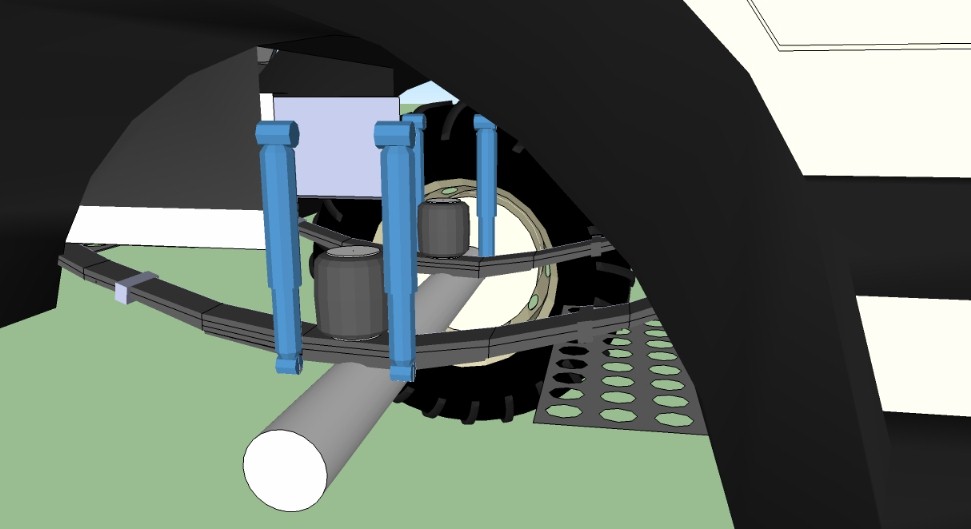

The shock absorber’s weird base with the plastic cylinder that guides the cabin when tilting back appears next. Here, to adapt the cabin suspension from Spare, the base must be modified putting a second cylinder to guide and also support the cabin in the front-aft direction. This is needed as the cabin will rest on the frontal suspension from Spare and on the “floating” rear coils from the original truck and much weight will be added on the rack.

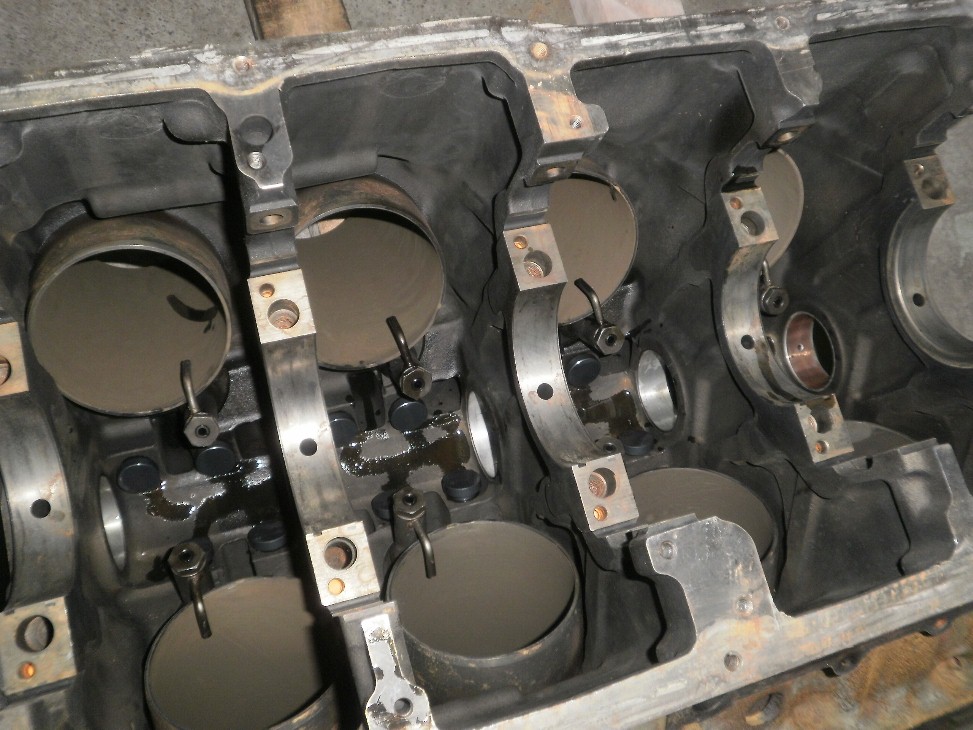

At the moment of taking the pictures to all the cables, tubing and Tecalan I felt shivers on my spine at the thought of the amount of work when it came the time of taking all of these off, cleaning and painting the frame and putting all back in order.

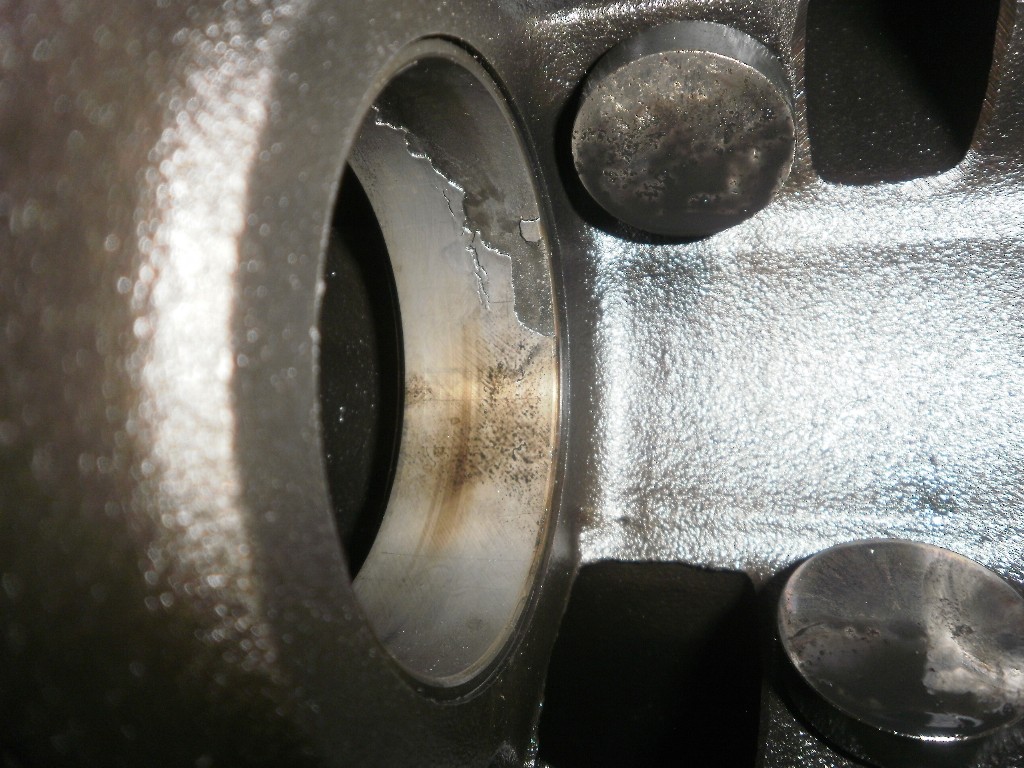

One of the postponed works was the one to be done to the exhaust. The idea was to lift the silencer as much as possible and to repair/replace the bumped tubing.

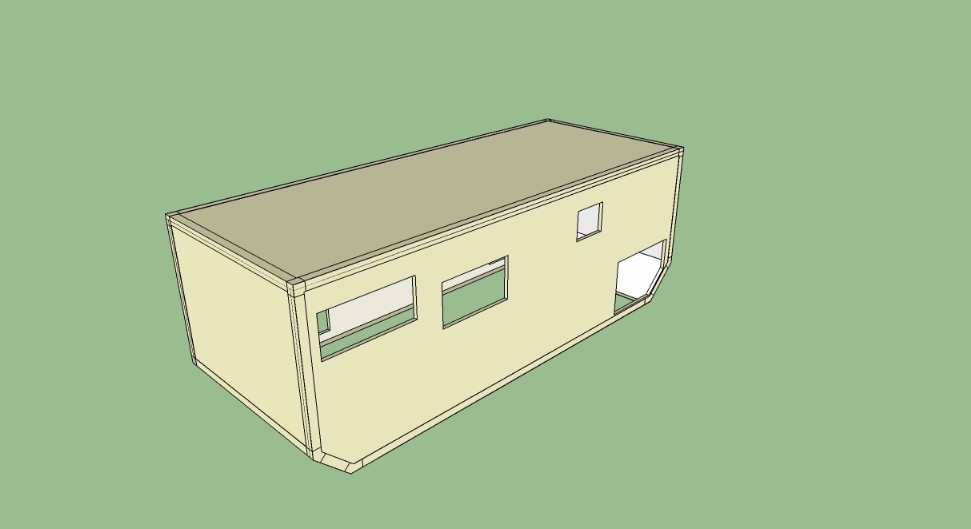

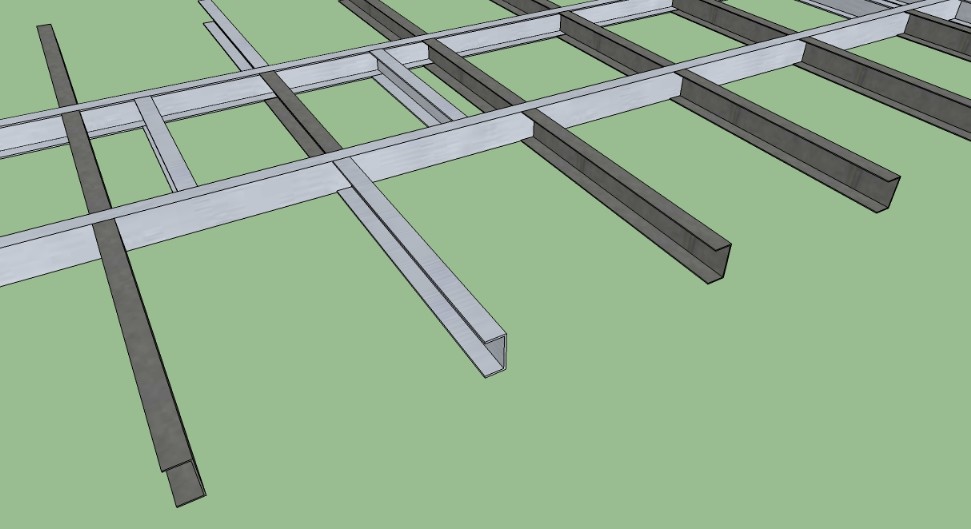

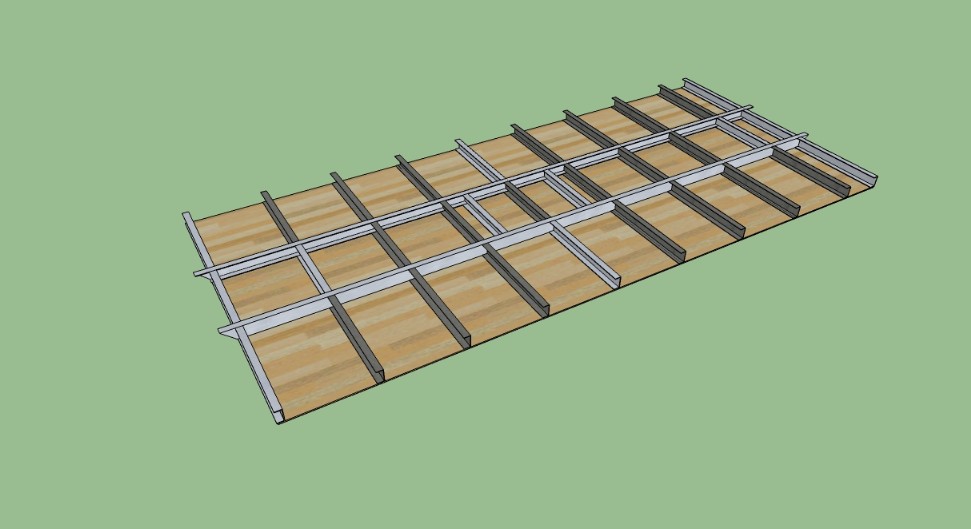

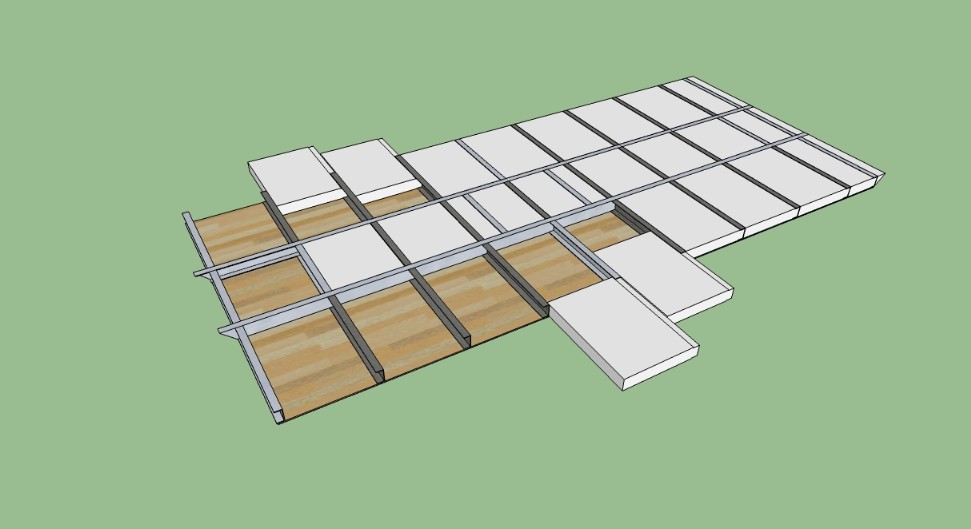

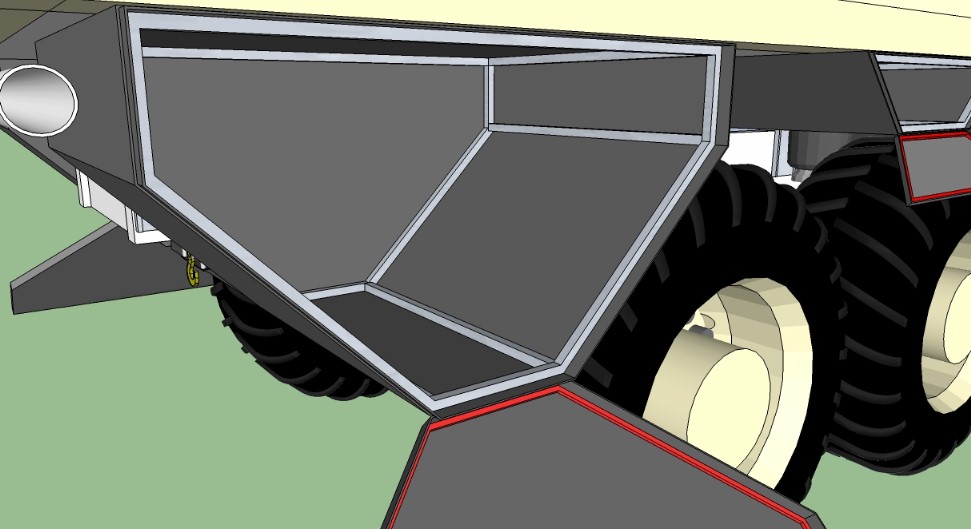

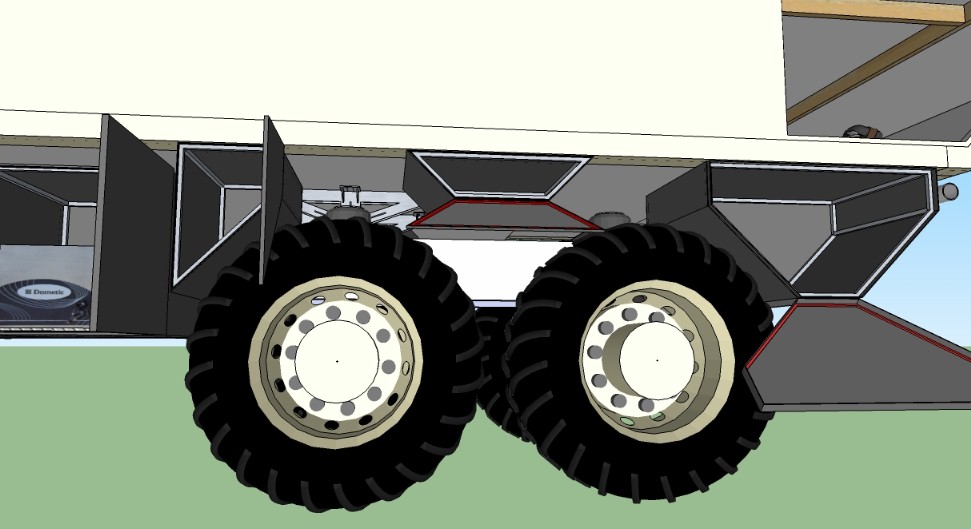

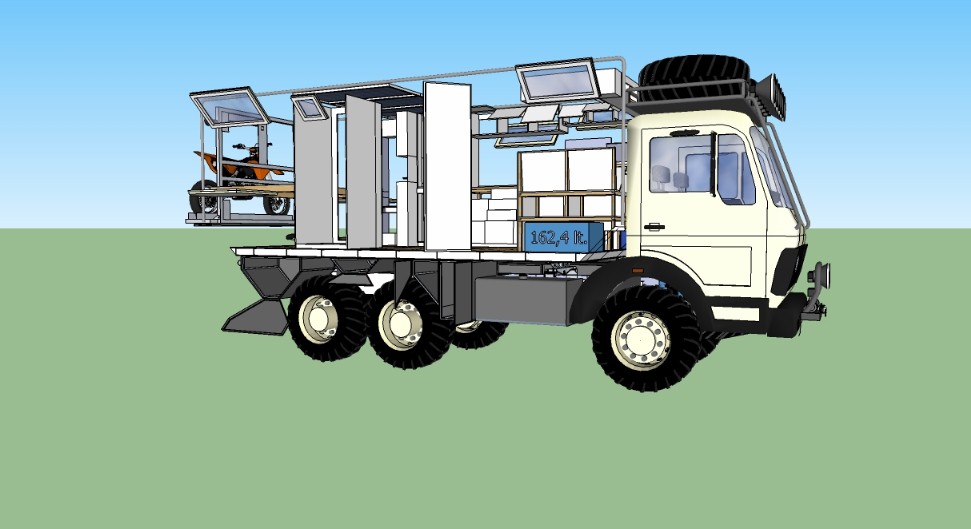

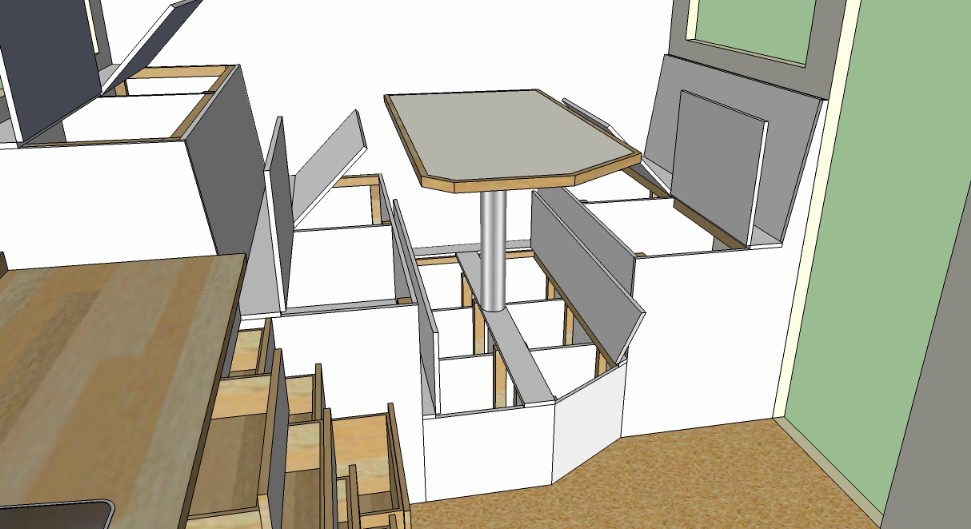

Did I say that to install the Box I need to stretch the chassis of the truck by 43 cm., reaching the maximum length permitted by law according to the wheel base? Well, to do that I need to take off the pretty much vulgar white painted pieces of steel from the side rails and put in some pieces from the untouched frontal part of the frame of Spare, the donor.

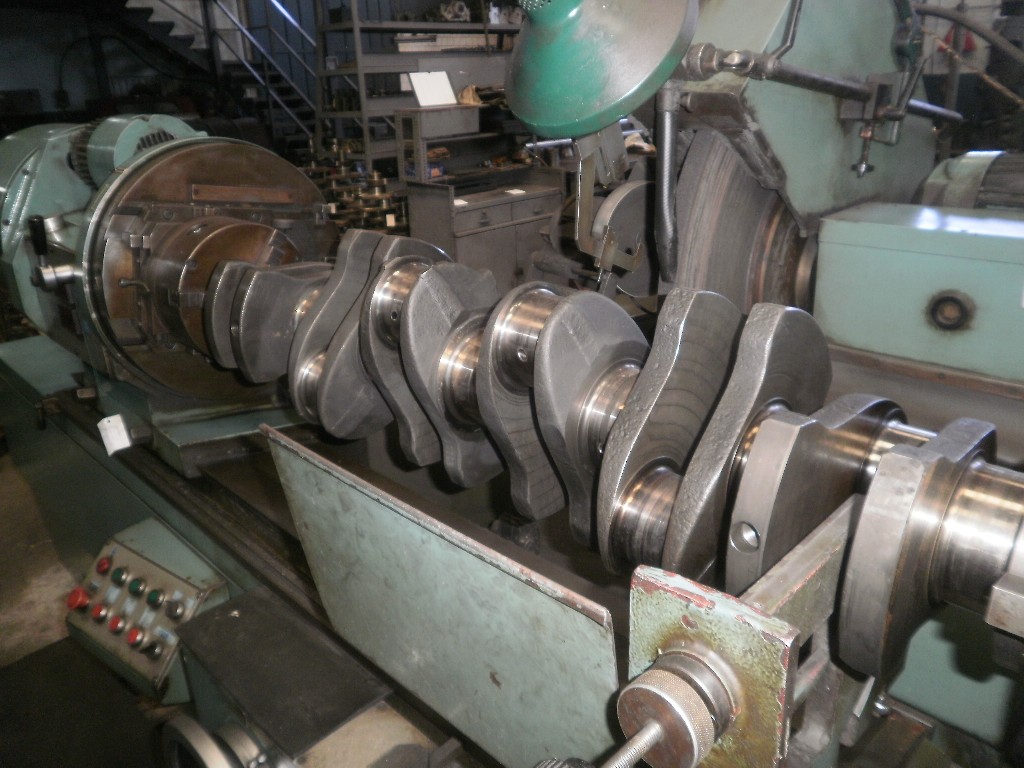

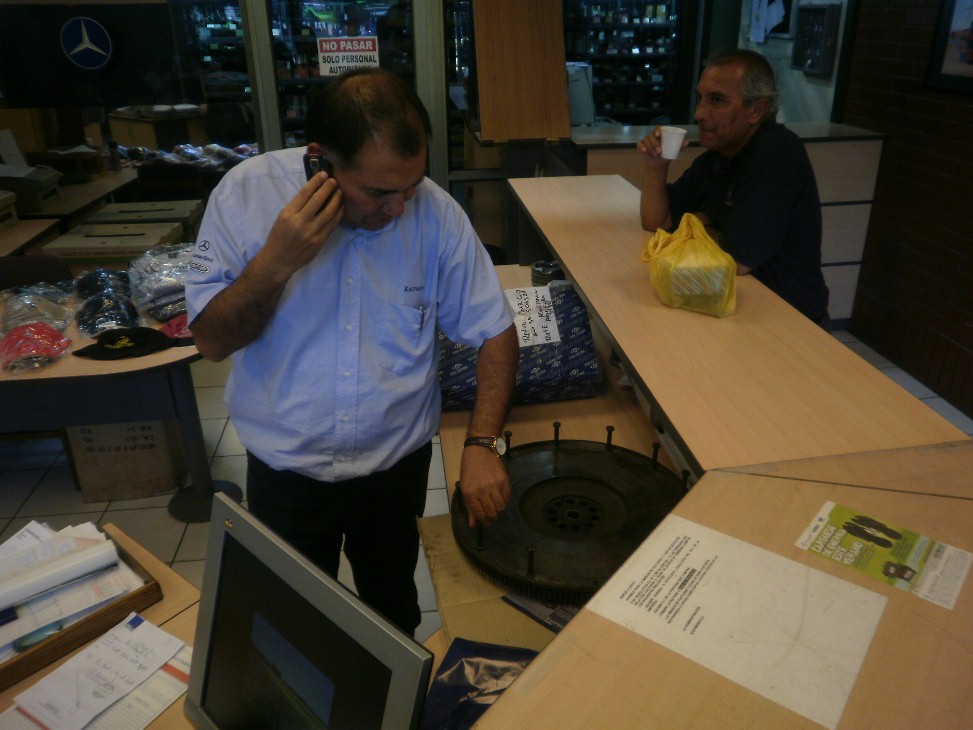

When I took off the engine I was so annoyed and tired that I abandoned/forgot the starter, holding there from its cables. With a better disposition I took it off and brang it to the shop for servicing; it would have to endure many more starts in the near future.

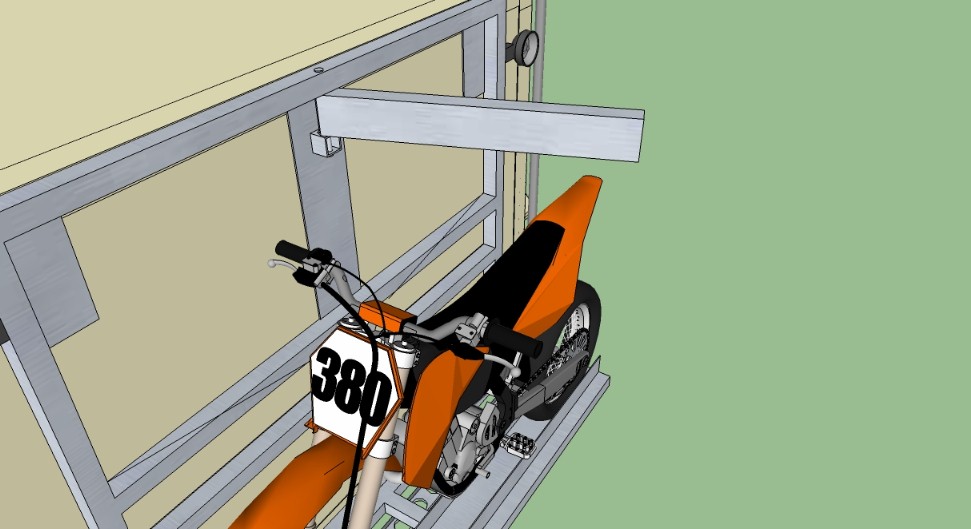

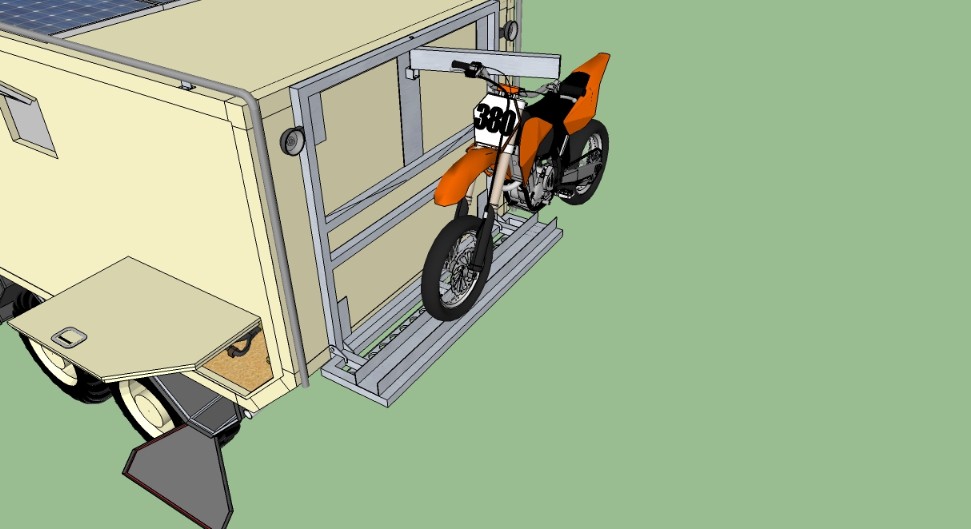

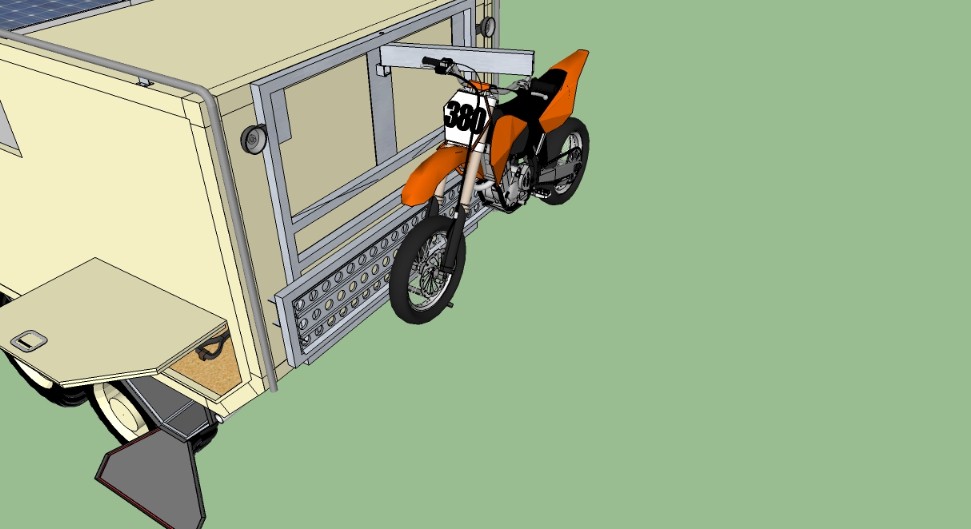

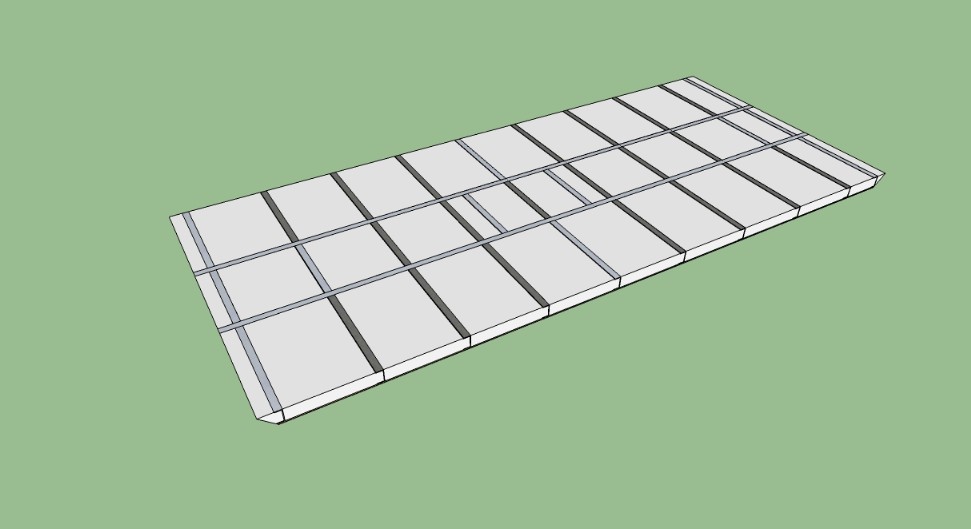

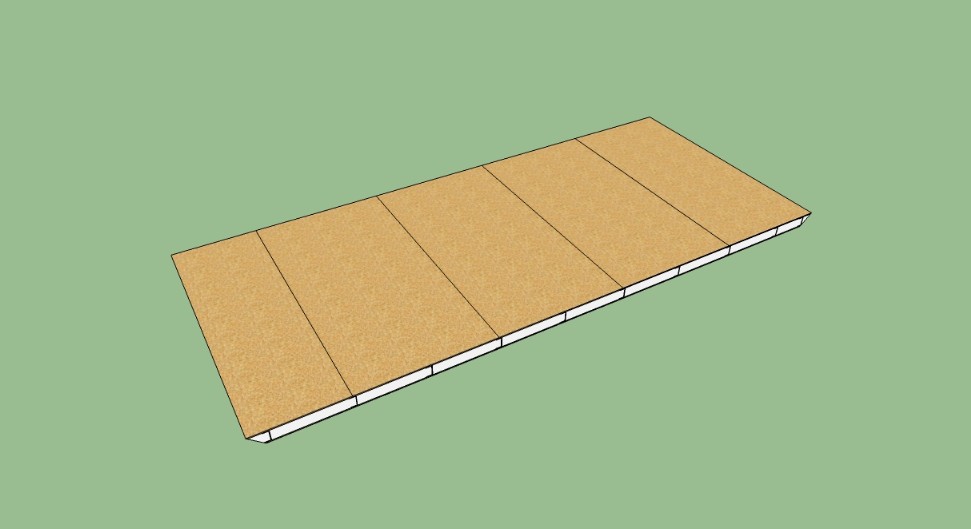

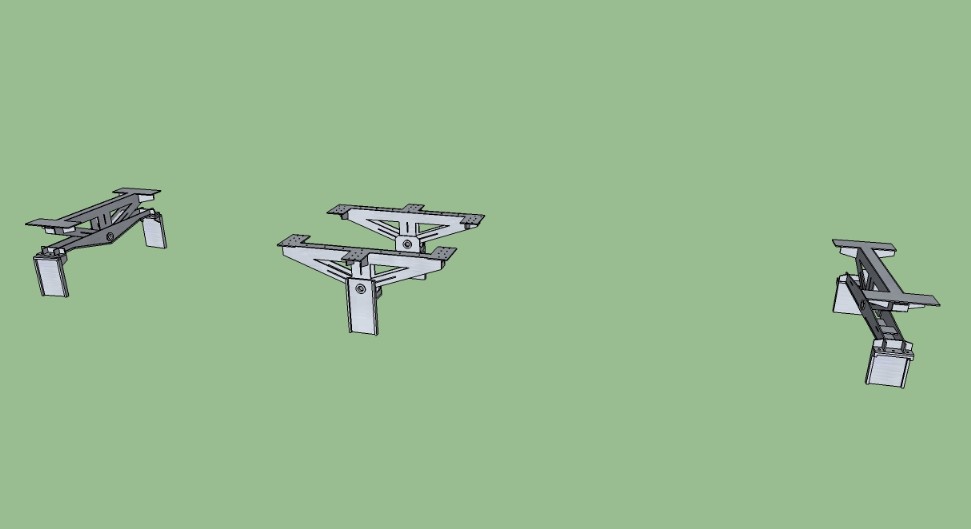

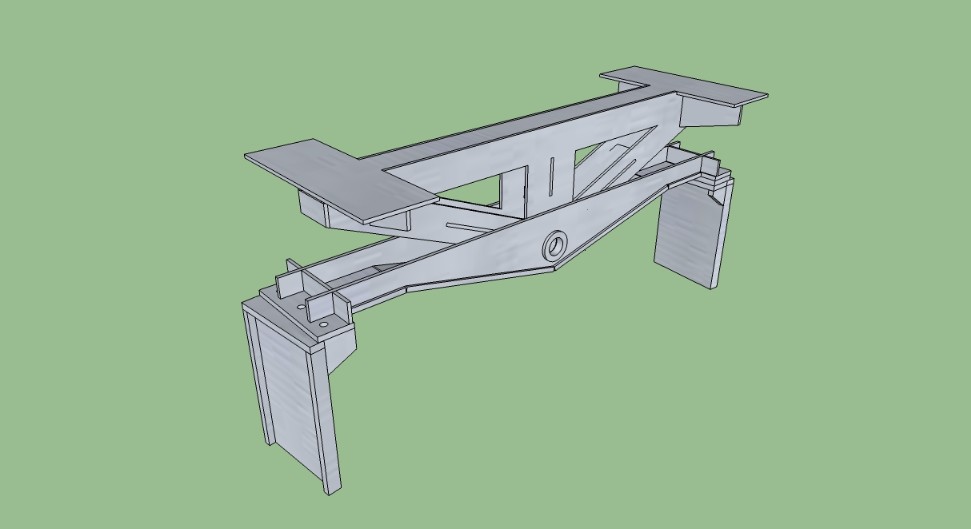

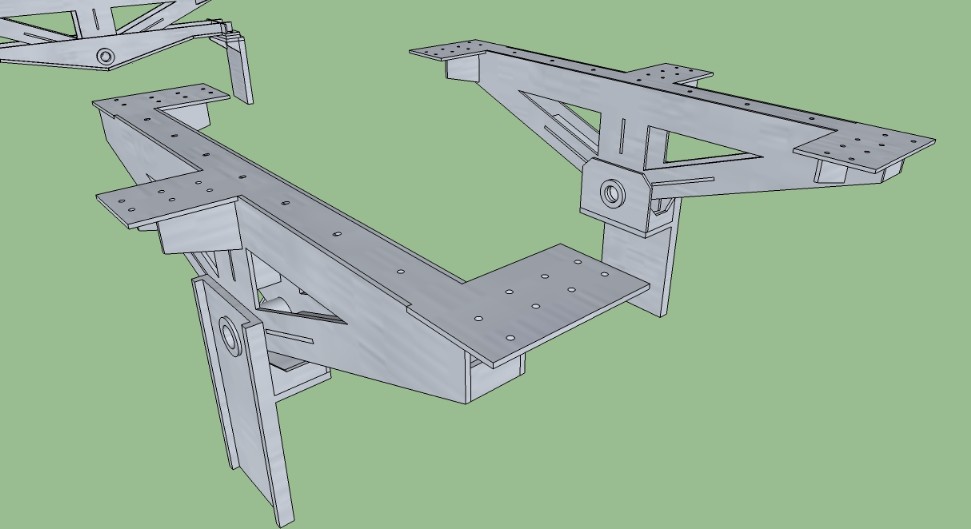

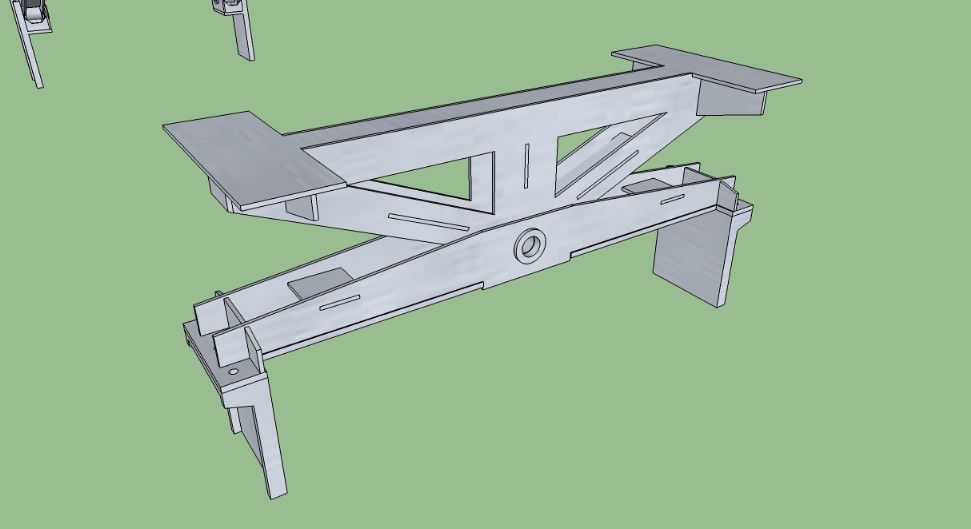

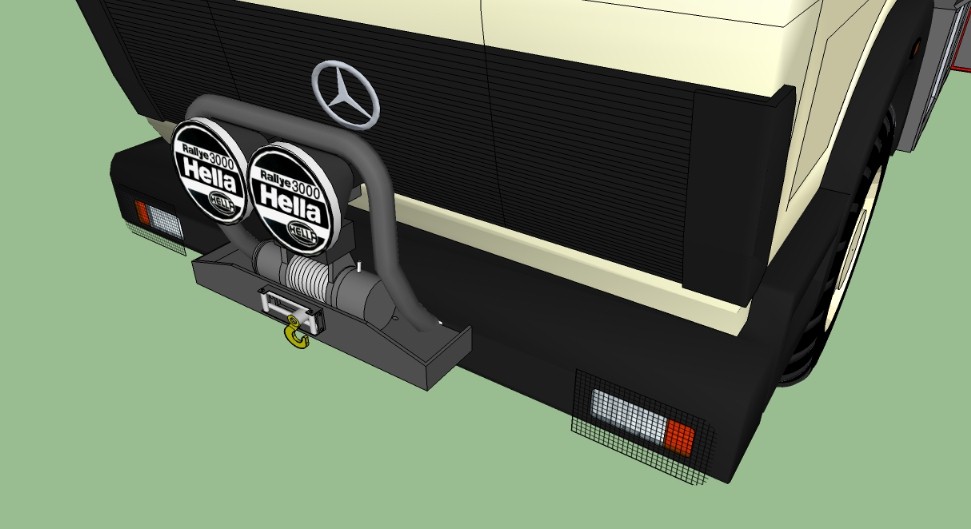

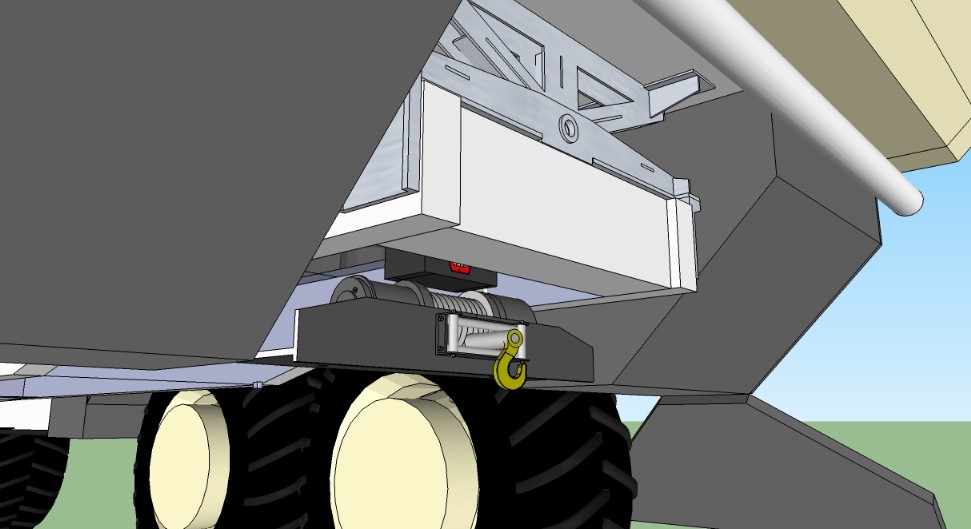

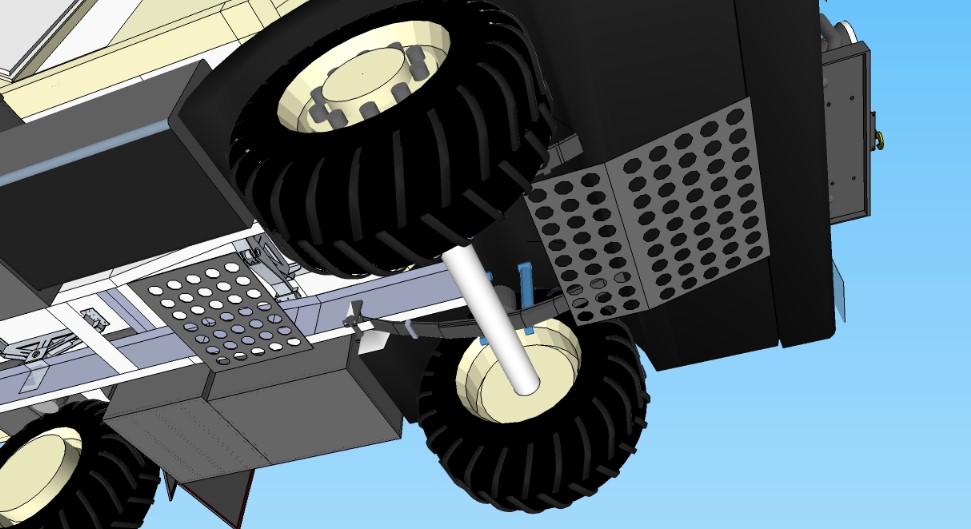

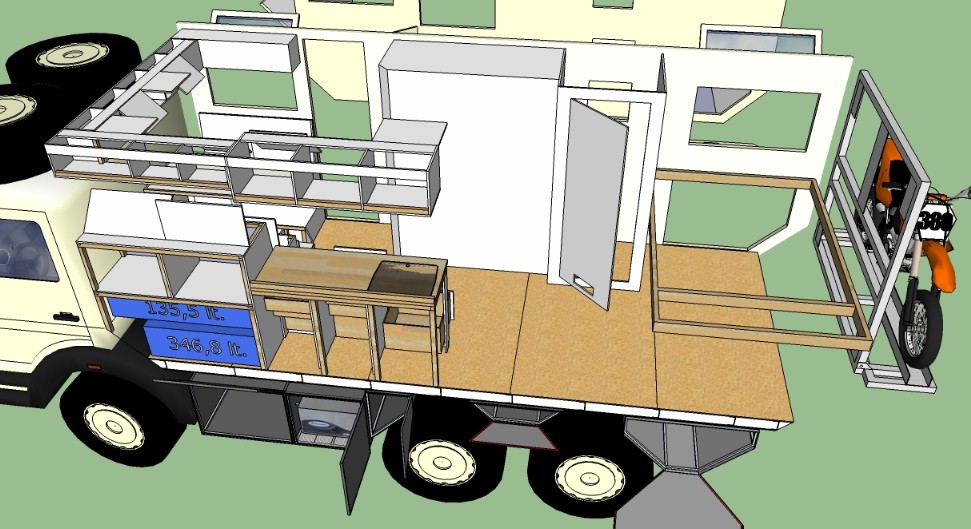

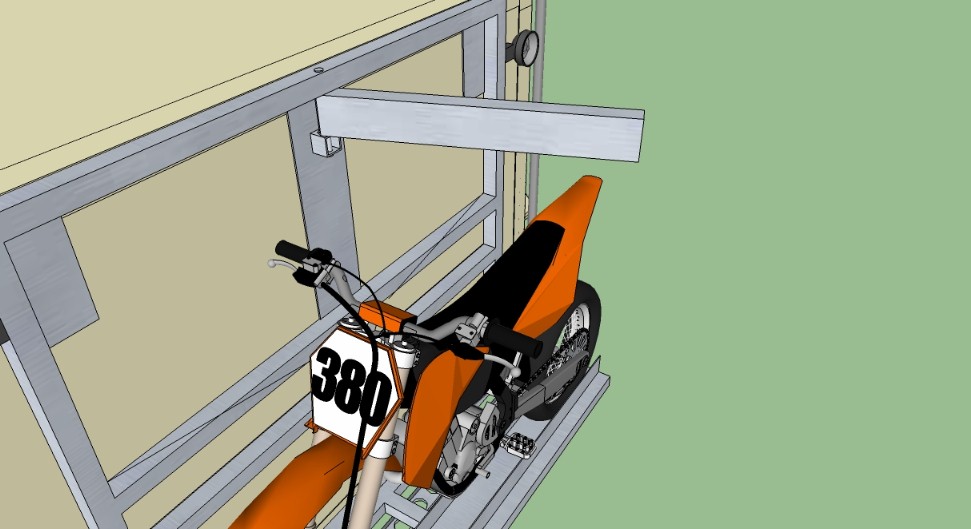

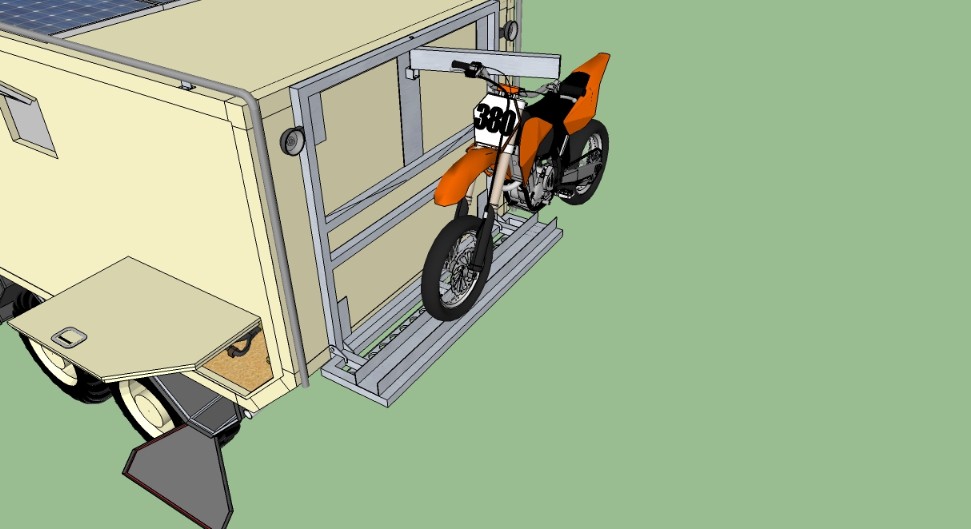

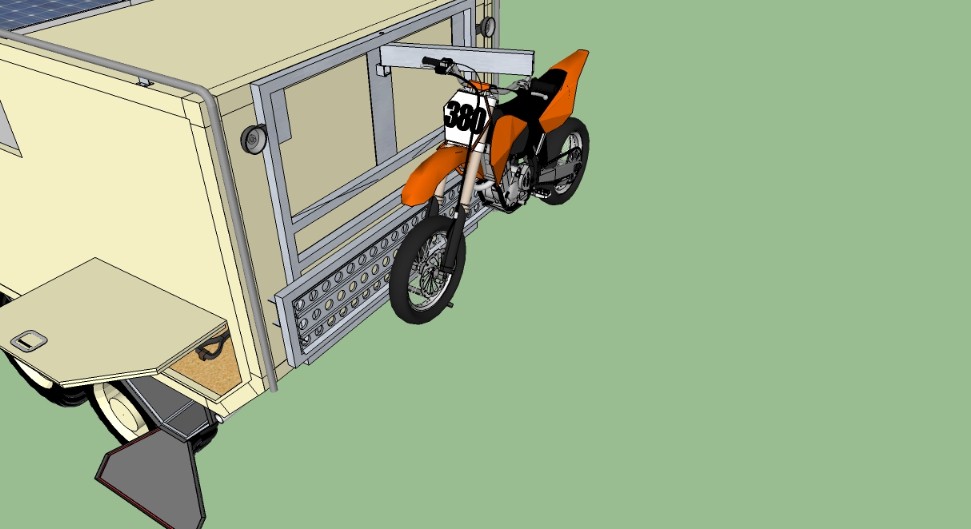

I simplified the pivoting arm to mount the motorcycle and the spare wheels on the rear rack with a single square section steel beam to allow the electric winch to be mounted directly under it. You can see how it works along with the pivoting base. I did not include neither the cable nor the winch, guess why. Underneath there will be the sand plates that, of course I yet need to acquire.

The rear lamps are the ones that I found late at night, and it seems that will remain there forever.

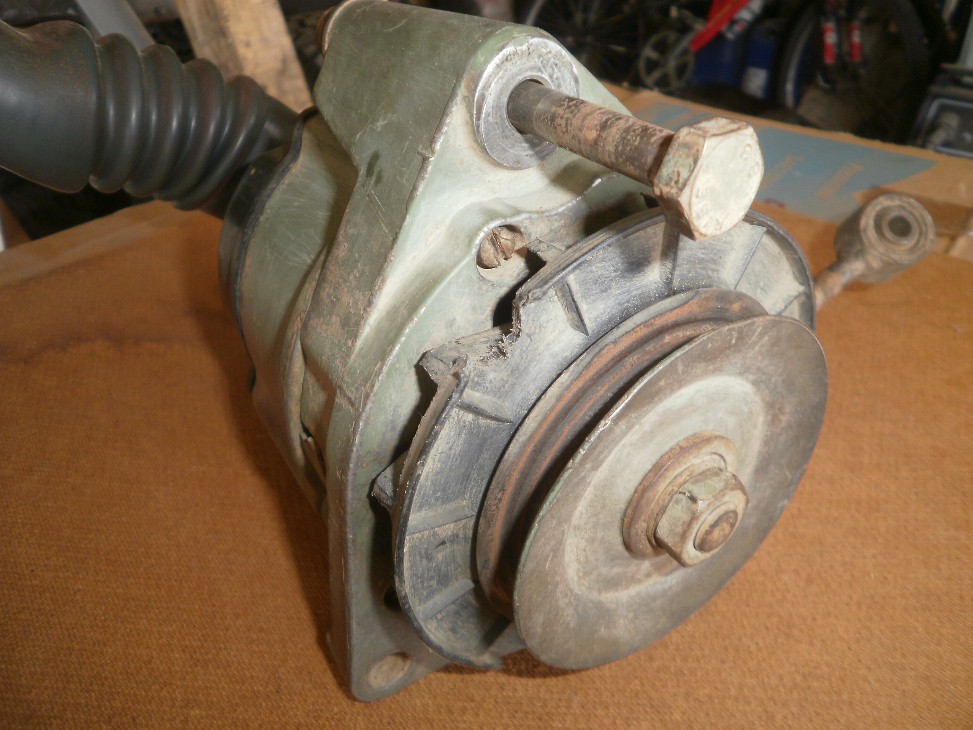

I asked Eduardo for the starter and the alternator to be taken to servicing and other things to be done during my vacations.

Some weeks before I had asked the good Lord for help to find the only piece of the Merkabah that certainly I would never find in a store, and without it the 6x6 wohnmobil would never be complete: the snorkel. With the snorkel the dust intake amount diminishes by 50% at least and it changes absolutely and drastically the look of the cabin and the whole vehicle, from a hardly tunned ice cream truck to a real allterrain motorhome. Well, something like it. I am full aware of my crazyness, never mind.

So, I was always alert and searching for the right truck with the snorkel I needed. As (almost) always I had a precise vision of what to expect, and I commented it to Carmen, my wife. But despite the attention and many trips around I never found it.

So the time came and we finally got the Terrano, prepared it along with the camping gear and went south, in worriless vacations. But the good Lord always hear what you ask Him for if you have enough faith and behave, so… guess what did I see with the corner of the eye at 120 km/hr, lost on a muddy and smokey yard, halfway between two distant cities on the big island of Chiloé, 1300 km. south from San Felipe? Yes, the wrecked orange cabin of the NG Mercedes with the snorkel waiting for me, just like the one of my vision.

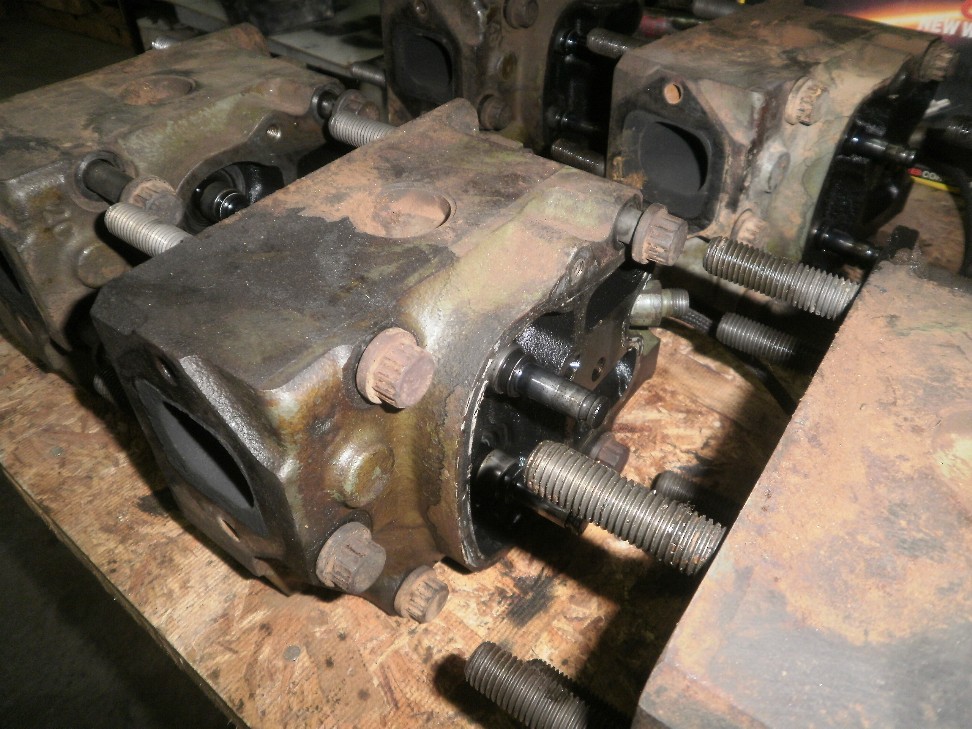

To make the story short, we stopped to reach information and drove on to the next city; I located the owner late in the afternoon and bought the snorkel by phone. I woke up early the next morning and I drove the 65 km. back to the yard and disassembled the snorkel with very inappropriate tools. It took me two and a half hours because the rust was terrible and every bolt represented a battle. I put the pieces in big plastic bags and accommodate them over the luggage on the back of the Terrano. I also got permission and took the plastic water reservoir for the windshield wiper but I had to cut the mounts because I lost the battle against the corrosion of the island.

With big acknowledgments to the big Chief and to Carmen’s patience I got back to pick her up and we resumed our trip. I put a picture of one of the best views from the last occidental and austral place you can reach by car on the island, near Cucao.